What is an airflow transducer?

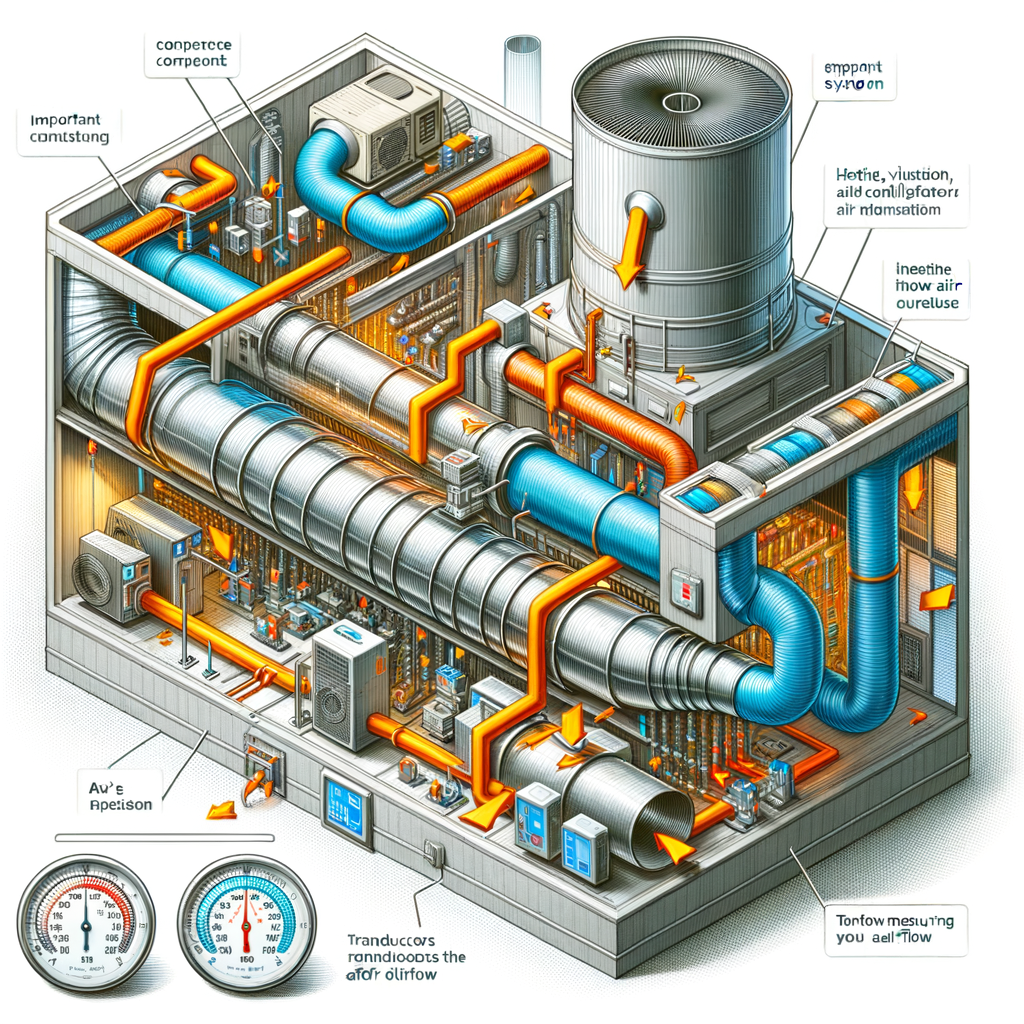

An airflow transducer is a sensor that measures a system's air movement rate. It converts airflow data into electrical signals for monitoring and control.

These transducers are commonly used in HVAC systems, medical devices, and industrial applications to ensure proper ventilation and efficiency.

They work using different principles like thermal, pressure-based, or ultrasonic sensing. Accurate airflow measurement helps maintain system performance, safety, and energy efficiency. Many industries rely on airflow transducers for real-time data and automation

How Does an Airflow Transducer Work?

An airflow transducer detects and converts airflow into an electrical signal for measurement and analysis. It uses various sensing methods, such as thermal, pressure differential, or ultrasonic technology, to determine the speed and volume of air movement.

Thermal sensors measure heat loss as air flows over a heated element, while pressure-based sensors detect changes in pressure to calculate flow rate. Ultrasonic sensors use sound waves to measure airflow velocity accurately.

The transducer then transmits this data to a monitoring system, enabling precise control in HVAC, medical, and industrial applications.

Definition and application of an airflow transducer

An airflow transducer is a device that measures the rate of air movement and converts it into an electrical signal for monitoring and control.

Applications:

- HVAC Systems: Ensures proper airflow for energy efficiency and indoor air quality.

- Medical Devices: Used in ventilators and anesthesia machines to monitor patient airflow.

- Industrial Automation: Controls airflow in manufacturing processes for safety and efficiency.

- Aerospace Engineering: Measures airflow in aircraft ventilation and engine systems.

- Environmental Monitoring: Tracks air movement in laboratories and cleanrooms

How does an airflow transducer measure air velocity?

1. Thermal Sensing

A hot and cold element detects temperature changes with airflow.

2. Pressure Differential

Measures pressure difference between two points to estimate airflow.

3. Ultrasonic Waves

It uses time delay or frequency shift of sound waves to measure air velocity.

4. Mechanical Sensors

A paddle or vane moves with the airflow and calculates speed.

5. Electronic Signal Conversion

Converts data into electrical signals and sends it to a monitoring system.

Common types of transducers used in airflow measurement

| Type of Transducer | Working Principle | Common Applications |

|---|---|---|

| Thermal Flow Transducer | Measures heat loss from a heated sensor element | HVAC, Medical Ventilators |

| Differential Pressure Transducer | Uses pressure difference to calculate airflow | Industrial Automation, Aerospace |

| Ultrasonic Flow Transducer | Uses sound waves to measure airflow velocity | Cleanrooms, Environmental Monitoring |

| Vane Anemometer | Rotating blades spin with airflow to measure speed | HVAC, Laboratories |

| Hot Wire Anemometer | A fine heated wire cools down with airflow, determining speed | Research, Automotive Industry |

| Mass Flow Sensor | Measures the mass of air passing through the sensor | Medical Devices, Automotive |

What are the key features of an airflow transducer?

- Measurement Technology –Whether it uses thermal, pressure-based, ultrasonic, or mechanical sensing.

- Accuracy & Sensitivity – The precision in detecting even minor changes in airflow.

- Response Time – How quickly it provides real-time airflow data.

- Output Signal Type – Analog, digital, or wireless communication for system integration.

- Operating Range – The range of airflow speeds it can measure effectively.

- Environmental Durability – Resistance to temperature, humidity, or contaminants.

- Power Consumption – Energy efficiency for long-term use in various applications

Accuracy and range of airflow transducers

Airflow transducers are designed to provide high accuracy in measuring air velocity and volume, ensuring precise monitoring in various applications. Their accuracy typically ranges from ±1% to ±5%, depending on the sensor type and technology used.

The measurement range varies widely, from 0.1 m/s to over 100 m/s, making them suitable for low-flow medical devices to high-speed industrial airflow systems.

Advanced models offer real-time calibration and compensation for environmental factors like temperature and pressure, enhancing reliability.

Durability: temporary vs permanent solutions

Temporary transducers are lightweight, portable, and designed for short-term monitoring, such as testing HVAC efficiency or conducting environmental studies.

In contrast, permanent transducers are built for long-term integration into systems, featuring robust materials, weather resistance, and self-calibration capabilities to ensure continuous performance.

Temporary solutions are cost-effective for diagnostics, while permanent options provide greater reliability and accuracy in industrial, medical, and aerospace applications.

The choice depends on usage requirements, environmental conditions, and long-term operational goals.

How can airflow transducers improve comfort in indoor environments?

Airflow transducers play an important role in improving ease and comfort in indoor environments. These devices accurately measure the flow rate, pressure, and temperature of air, allowing HVAC systems to be controlled at an optimal level.

This helps maintain balanced air circulation in each room, preventing excessive heat or cold. Due to the high accuracy of transducers, energy consumption is reduced, which not only enhances comfort but also saves energy.

These systems also monitor air quality, ensuring fresh and clean air, making the home or office environment more comfortable. Overall, airflow transducers help manage indoor comfort smartly and efficiently.

Using airflow data for enhanced indoor environment quality

This data helps optimize HVAC systems, ensuring balanced ventilation and temperature control in every room. By analyzing airflow details, we can monitor air quality, reduce CO2 and pollutant levels, and ensure a fresh air supply.

Additionally, this data improves energy efficiency, allowing systems to operate more effectively and reducing excessive electricity consumption. Smart ventilation systems use airflow data in real-time to adjust airflow based on occupancy and outdoor conditions, making the indoor environment more comfortable and healthy.

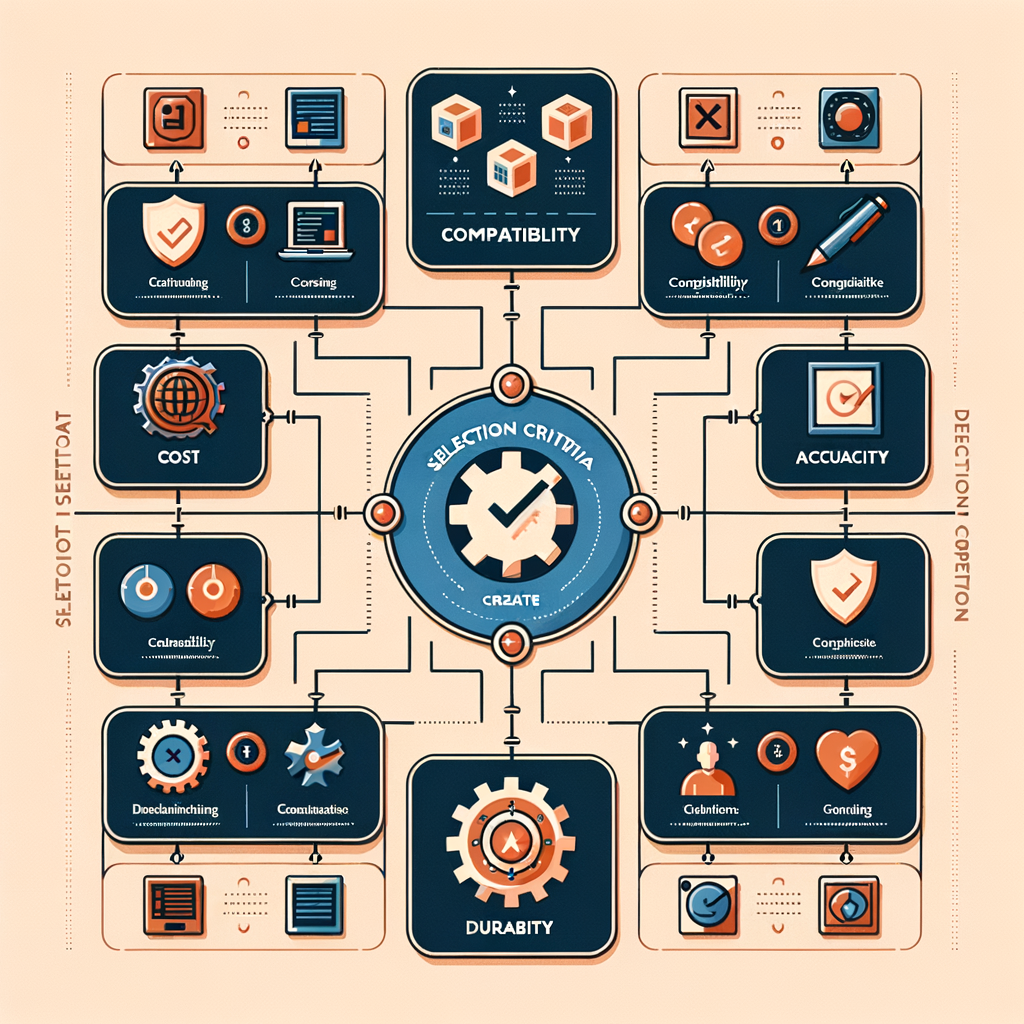

What should you consider when selecting an airflow sensor?

Measurement Range

The range of air velocity the sensor can effectively measure.

Accuracy and Precision

The ability to accurately and precisely measure airflow.

Sensor Type

Choose between thermal, pressure-based, ultrasonic, or mechanical types.

Response Time

How quickly the sensor provides real-time data.

Output Signal Type

Compatibility for analog, digital, or wireless communication.

Durability

Ability to withstand environmental conditions such as temperature and humidity.

Power Consumption

Energy efficiency for long-term use.

Size and Installation

Sensor size and ease of installation.

Cost

Cost-effectiveness according to budget.

Integration Capabilities

Compatibility and integration with existing systems.

Understanding the output signals from airflow transducers

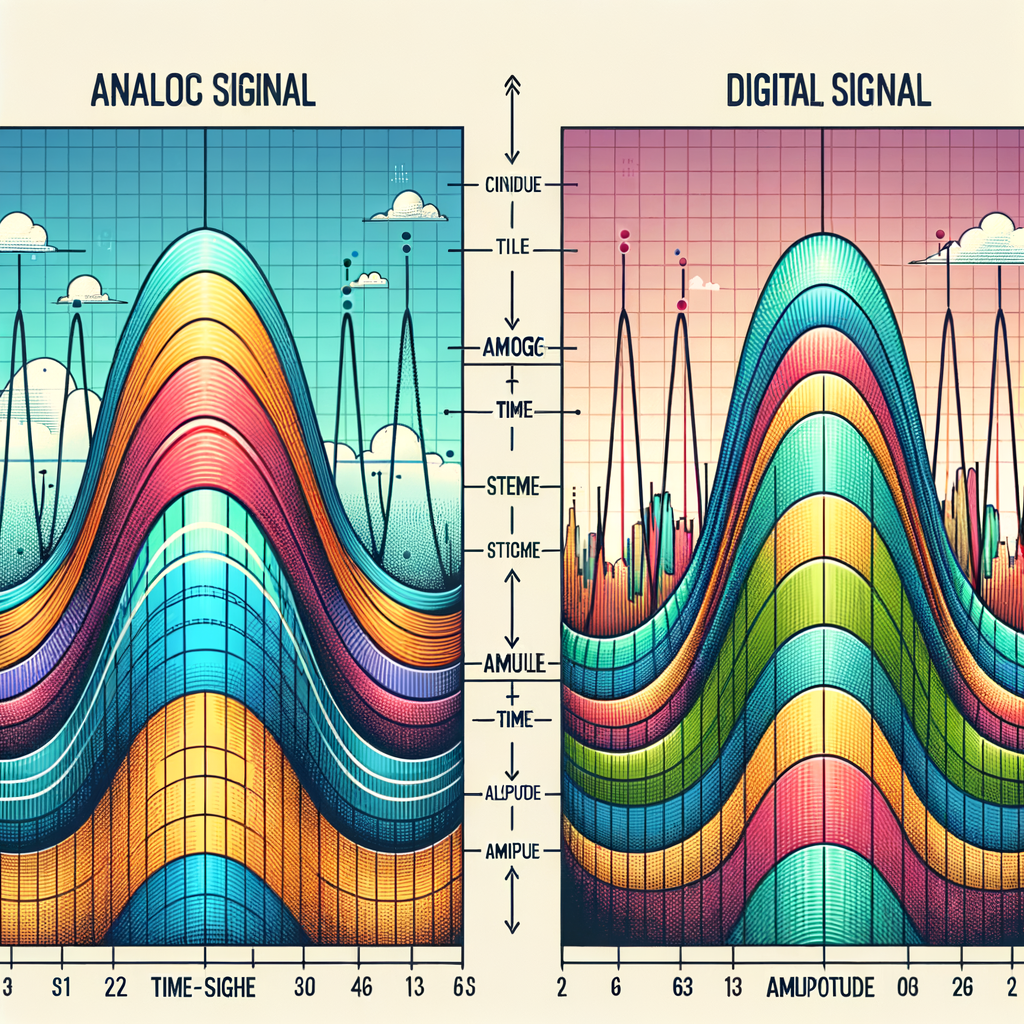

Airflow transducers convert the speed and volume of airflow into electrical signals, which help control HVAC systems. These signals can be transmitted via analog, digital, or wireless communication.

Analog signals are in the form of voltage or current, while digital signals provide numerical data. Wireless signals enable real-time monitoring and remote access. These output signals are used to monitor system performance, energy efficiency, and air quality.

The accuracy and response time of the transducers affect the quality of the signals, making them crucial for precise airflow management in various applications

What are the benefits of using an airflow transducer in manufacturing?

Improved Process Efficiency

Airflow transducers provide accurate airflow measurements, ensuring optimal ventilation and system performance in manufacturing processes, like drying, cooling, and material transport.

Enhanced Product Quality

By maintaining consistent airflow, transducers prevent variations in processes like coating or drying, which improves the quality and uniformity of the final product.

Energy Efficiency

Real-time monitoring helps optimize airflow systems, reducing energy consumption and operational costs.

Safety and Compliance

Accurate airflow control ensures a safer working environment by preventing hazardous gas accumulations or overheating in industrial setups.

Reduced Downtime

Constant monitoring detects system inefficiencies or potential issues early, reducing unplanned maintenance or breakdowns.

Environmental Benefits

Consistent airflow reduces emissions and maintains regulatory compliance in processes involving exhaust or particulate control.

Versatility

Transducers are compatible with various manufacturing setups, including HVAC systems, assembly lines, and cleanrooms, providing flexibility across industries.

Cost-effectiveness of airflow measurement in production

Accurate airflow sensors increase production efficiency and reduce energy wastage. Cheap or low-quality sensors can provide incorrect readings, which may lead to faulty products and increased maintenance costs.

Advanced digital sensors have a higher initial cost, but they prove to be more beneficial in the long run. Automation and smart monitoring systems improve airflow control. Manual airflow measurement can be quite expensive and time-consuming. Therefore, it is essential to maintain a balance between cost and performance.

Available information on airflow transducer technology

The Applied Physics USA website provides comprehensive information on airflow transducer technology. It offers various models like 6332/6332D and 6333, featuring analog output and smart probe technology.

The smart probe technology allows probe replacement without recalibration, ensuring easy maintenance. The 6333 model has a compact design, making it easy to integrate into different systems.

Models Available 6332/6332D

It also supports up to 15 different probes, enabling simultaneous measurement of airflow, temperature, and humidity. Additionally, vent-type airflow transmitters like AT400 and TAT420 are available for specialized applications.

The website includes detailed product specifications, features, and benefits, helping users select the right airflow transducer for their needs.

Conclusion

Airflow transducers play a crucial role in monitoring and controlling air movement in various applications. They ensure accurate measurement of airflow, temperature, and humidity for improved efficiency.

Advanced models with smart probe technology provide easy maintenance and reliability. Compact designs allow seamless integration into HVAC and industrial systems. The availability of multiple probe compatibility enhances functionality. Choosing the right transducer depends on application requirements and industry standards.

FAQs

1. Can airflow transducers measure multiple parameters simultaneously?

Yes, advanced airflow transducers can measure air velocity, temperature, and humidity at the same time, providing comprehensive data for better air control and system optimization

2. How does smart probe technology benefit airflow transducers?

Smart probe technology allows probes to be replaced without recalibration, reducing downtime and maintenance efforts.

3. Where are airflow transducers commonly used?

They are used in HVAC systems, industrial automation, cleanrooms, and research laboratories for precise air control.

4. What factors should be considered when selecting an airflow transducer?

Key factors include accuracy, response time, compatibility with other systems, and environmental conditions.

5. How do airflow transducers improve energy efficiency?

By providing real-time airflow data, they help optimize ventilation systems, reducing energy waste and operational costs.