A cleanroom fogger is a specialized device used in controlled environments to generate ultra-fine fog for airflow visualization and contamination control.

It helps detect airflow patterns, turbulence, and leaks in cleanrooms, ensuring compliance with industry standards in pharmaceuticals, semiconductor manufacturing, and biotech labs.

By producing a consistent and uniform mist, the fogger makes invisible air currents visible, allowing engineers to optimize ventilation and filtration systems.

This technology is essential for maintaining high-purity environments where even microscopic particles can affect product quality and safety.

A cleanroom fogger operates by generating ultra-fine fog particles that disperse into the air, making invisible airflow patterns visible. It typically works using the following steps:

The fogger uses deionized water, purified water, or a special fogging solution to create mist. Some advanced models use ultrasonic or vaporization technology for ultra-fine particle production.

Once the fog is generated, it is released into the cleanroom environment, where it spreads evenly without contaminating the air.

The fine fog particles follow the air currents, revealing airflow direction, turbulence, and any unwanted leaks or dead zones in the cleanroom.

Engineers and technicians analyze the fog movement to identify air leaks, pressure imbalances, or inefficient ventilation, allowing them to fine-tune the cleanroom’s filtration and air control systems.

High-quality cleanroom foggers ensure they dissipate completely without leaving any residue, making them ideal for pharmaceutical, semiconductor, and biotech applications.

Cleanroom foggers play a crucial role in maintaining sterile environments through the application of precise physical principles. These devices generate ultra-fine particles of disinfectant solution, typically ranging from 1-5 microns in size, which remain suspended in the air due to their small mass and aerodynamic properties.

The fog particles follow thermal currents and Brownian motion patterns, allowing them to reach and settle on all surfaces within the cleanroom, including difficult-to-access areas.

The effectiveness of these foggers relies on the physical concepts of fluid dynamics, particle dispersion, and surface tension, ensuring uniform coverage and maximum contact time between disinfectant and surfaces.

In modern cleanroom facilities, foggers are often integrated with automated monitoring systems that use advanced sensors to optimize particle distribution and maintain ideal humidity levels based on real-time environmental data

Cleanroom foggers are commonly used in industries where absolute sterility is critical, such as pharmaceuticals and biotechnology, ensuring that products and processes remain free from contamination.

They also play an essential role in medical device manufacturing, where even minute particulates can impact product safety and efficacy.

In the electronics and semiconductor sectors, foggers help control the environment to prevent damage from contaminants during sensitive assembly processes.

Additionally, the aerospace industry relies on these systems to maintain the stringent cleanliness required in components and assembly areas

Emerging applications in food manufacturing and research laboratories further illustrate the versatility and importance of cleanroom foggers in modern controlled environments.

Generates ultra-fine disinfectant particles that uniformly reach all surfaces, ensuring thorough decontamination.

Helps maintain a contaminant-free environment by ensuring effective distribution, which is critical to ISO suite standards.

Assists in visualizing airflow and determining room pressurization, thereby streamlining recertification and compliance checks.

Supports adherence to strict ISO standards and regulatory guidelines by maintaining controlled, sterile conditions.

Reduces labor-intensive cleaning practices and minimizes downtime, ultimately lowering operational costs

| Specification | Value/Range | Description |

|---|---|---|

| Fog Output | 0.26 cubic meters per minute (9 CFM) | It provides a consistent and steady fog flow that is ideal for airflow visualization in small-scale setups. |

| Fog Density | 57 ml per minute | Ensures sufficient fog concentration for effective visualizing of airflow patterns. |

| Operation Duration | Approximately 50 minutes | Typical continuous fog generation per water fill cycle |

| Water Volume Capacity | 3.75 liters | Designed to operate with DI water, sterile water, or water for injection within a single cycle. |

| Piezo Devices | 9 high-performance piezo transducers | Generates the fog by ultrasonic mechanism, ensuring uniform droplet production |

| Droplet Size | 8-10 microns | Optimized for creating a visible yet safe fog that evaporates properly within airflow streams. |

| Visible Fog Distance | Around 7-8 feet | Provides a clear visual representation of airflow in controlled environments |

| Power Requirements | 110 VAC or 220 VAC | Flexible power options to meet various facility standards. |

| Design and Portability | Compact, lightweight, portable | Facilitates ease-of-use in fume hoods, glove boxes, and small cleanroom applications. |

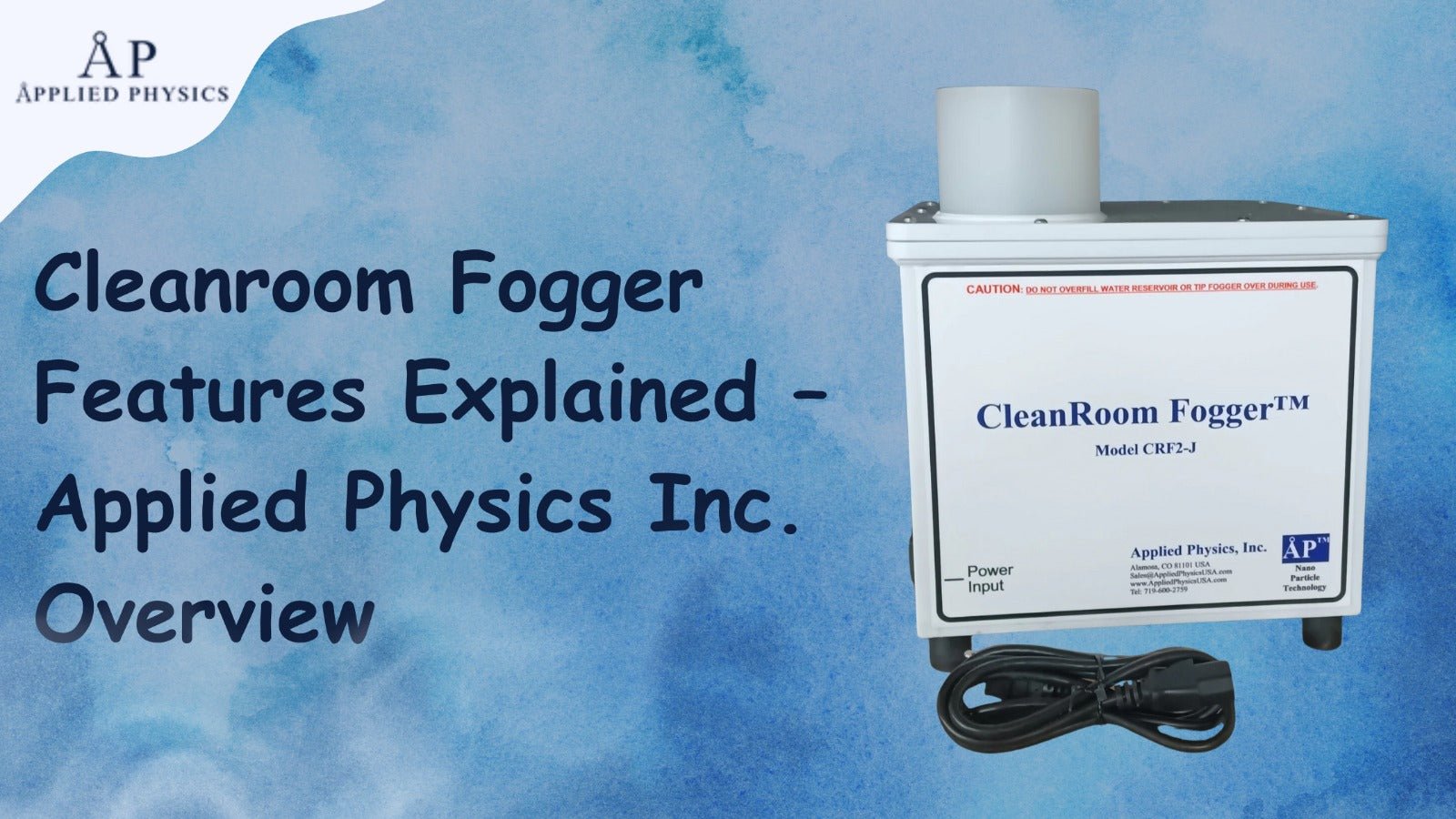

The CRF2 Cleanroom Fogger boasts an output capacity of 0.26 cubic meters of fog per minute, which translates to approximately 9 cubic feet per minute (CFM).

This consistent and robust fog production makes it well-suited for visualizing airflow patterns, identifying potential contamination risks, and ensuring proper cleanroom protocols are maintained.

The fogger operates at an output capacity of 0.26 cubic meters per minute, ensuring consistent fog generation.

This output is facilitated by high-performance piezo transducers, which use ultrasonic vibrations to produce a fine mist.

The controlled output helps in visualizing airflow patterns by dispersing the fog uniformly across the cleanroom.

The steady emission rate guarantees that the fog reaches all areas of the room, aiding in the detection of turbulence and dead zones.

The precise output supports facility evaluations and recertification processes by providing reliable, measurable data on air movement within ISO-controlled environments

Since 1992, Applied Physics Corporation has been a leading global provider of precision contamination control and metrology standards. We specialize in airflow visualization, particle size standards, and cleanroom decontamination solutions for critical environments.