In the precise world of semiconductor manufacturing, plasma etch selectivity, the ability to remove a specific material layer while leaving the underlying layer intact,t is paramount.

As device nodes shrink to the nanometer scale, traditional trial-and-error methods for tuning etch processes are no longer sufficient. The frontier of yield improvement now lies in optimizing gas flow dynamics.

By mastering the fluid mechanics within the process chamber, engineers can manipulate plasma density, ion flux, and chemical species distribution to achieve superior selectivity and uniformity.

This article explores the critical role of gas flow optimization in modern plasma etching.

Gas flow is not merely a transport mechanism; it is a control knob for the chemical and physical nature of the plasma.

The distribution of etchant gases (such as $Cl_2$, $SF_6$, or $C_4F_8$) directly dictates the local etch rate across the wafer.

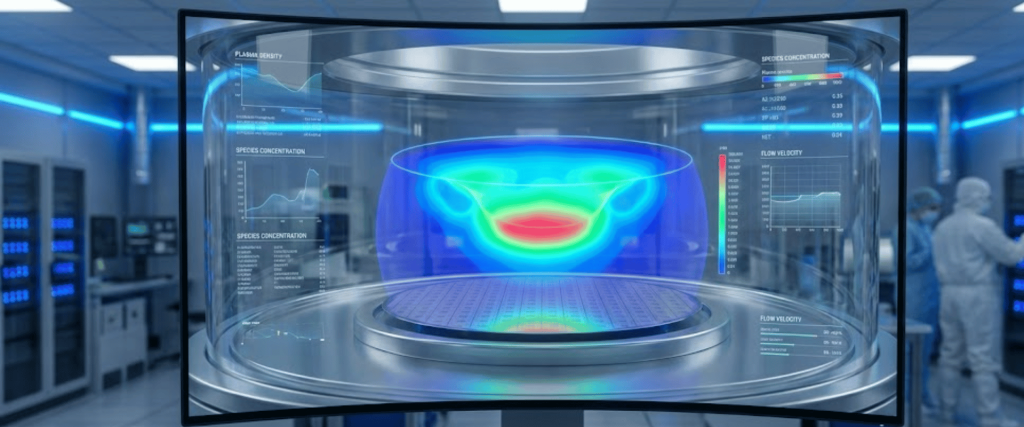

Modern optimization relies heavily on Computational Fluid Dynamics (CFD). Before a single wafer is processed, engineers use high-fidelity simulations to model the reactor environment.

CFD allows for the visualization of radial density profiles.

For instance, in a silica etch process using fluorocarbon gas, the ratio of polymerizing species ($CF_2$) to etching species ($F$) determines selectivity to the underlying silicon. CFD helps design flow baffles that maintain this optimal ratio across the entire wafer surface.

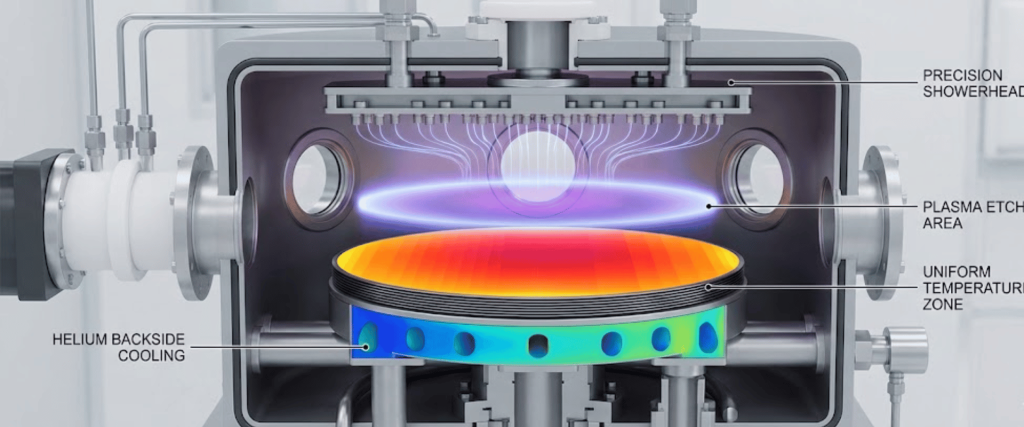

Gas flow is tightly coupled with heat transfer. Cooling gases (like Helium backside cooling) and the temperature of the incoming process gas affect the wafer surface temperature.

Since etch selectivity is often temperature-dependent, uniform gas flow ensures uniform thermal profiles, preventing hot spots that degrade selectivity.

Optimizing dynamics often requires specialized hardware designed to shape the gas flow path.

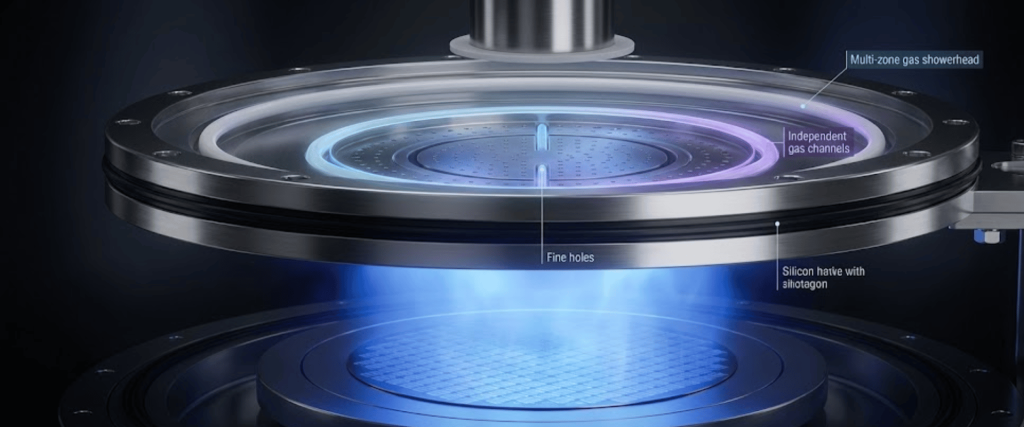

The showerhead is the primary delivery system. Modern multi-zone showerheads allow.

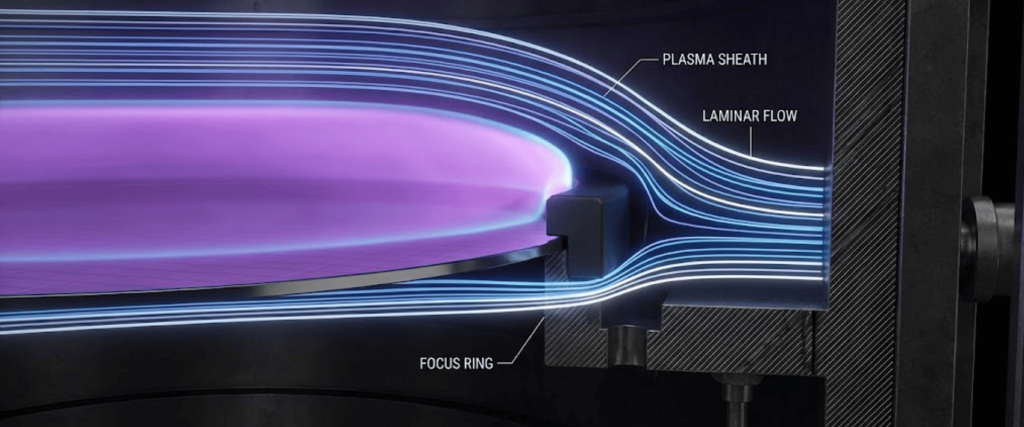

The wafer edge is a notorious source of yield loss due to discontinuities in the electrical and fluid environment. Focus rings are used to extend the plasma sheath, but they also influence gas flow.

Optimized focus ring designs minimize turbulence at the wafer edge, ensuring that reactant supply remains constant right up to the bevel.

Beyond hardware, the operational parameters of gas flow are critical for enhancing selectivity.

| Parameter | Effect on Dynamics | Impact on Selectivity |

|---|---|---|

| Total Flow Rate | Changes residence time and pumping speed. Higher flow can remove byproducts faster and prevent etch stop in deep trenches, but may dilute reactive species. | Can improve selectivity by reducing byproduct buildup, but too high a flow may lower selectivity due to reduced reactive concentration. |

| Gas Mixing Ratios | Alters the chemical composition of the plasma. | Precise mixing (for example, adding to $C_4F_8$) controls the polymer passivation layer, which is critical for high-selectivity etching. |

| Pulsed Gas Injection | Creates transient flow conditions. | Enables cyclic processes (such as the Bosch process) where etch and passivation steps are separated in time, allowing very high selectivity. |

The next leap in optimization is the integration of Artificial Intelligence (AI) with mass flow controllers (MFCs). AI algorithms can analyze real-time sensor data (OES, interferometry) to dynamically adjust gas flow profiles on the fly.

This self-tuning capability compensates for chamber wall conditioning effects and drift, ensuring that selectivity remains stable over thousands of RF hours.

Optimizing gas flow dynamics is a critical requirement for achieving high-fidelity plasma etching in advanced semiconductor manufacturing.

By integrating computational fluid dynamics (CFD) with precision hardware like multi-zone showerheads, engineers can overcome uniformity challenges and maximize etch selectivity.

As device nodes continue to shrink, mastering these complex flow regimes will remain the cornerstone of high-yield fabrication and next-generation device performance.

Residence time determines how long reactive species and byproducts remain in the chamber. A shorter residence time clears byproducts quickly, which is good for avoiding etch stops, while a longer residence time allows for higher dissociation of gases, potentially improving the selectivity between the target material and the mask.

A multi-zone showerhead allows engineers to independently control gas flow rates at the center and the edge of the wafer. This capability is essential for correcting the bullseye effect a common non-uniformity issue ensuring that the etch rate and selectivity are consistent across the entire wafer surface.

Yes, modern Computational Fluid Dynamics (CFD) are highly accurate in modeling gas velocity, pressure distribution, and species concentration. These simulations allow process engineers to visualize and troubleshoot dead zones or turbulence before running actual wafers, significantly reducing the cost and time required for process development.

Since 1992, Applied Physics Corporation has been a leading global provider of precision contamination control and metrology standards. We specialize in airflow visualization, particle size standards, and cleanroom decontamination solutions for critical environments.