Applied Physics — Industrial & Clinical Process Equipment for Cleanroom, Semiconductor & Medical Manufacturing

Applied Physics designs and manufactures validation, metrology, contamination control and laboratory systems used in pharmaceutical, semiconductor fabrication and clinical environments worldwide.

Airflow visualization • Particle metrology • Calibration wafer standards • Biological safety cabinets • SMT production lines • Core laboratory analyzers

Since 1992 — Airflow Visualization • Semiconductor Metrology • Clinical & Laboratory Equipment

Founded in Colorado in 1992 and now headquartered in Tampa, Florida, Applied Physics designs and manufactures precision equipment used across semiconductor fabrication, pharmaceutical cleanrooms, laboratories, and medical facilities worldwide. Our technologies support contamination control, airflow validation, particle metrology, sterilization, and healthcare instrumentation.

Applied Physics supports the semiconductor and electronics manufacturing industries with both precision metrology standards and complete electronics production equipment, allowing facilities to validate contamination control while also building finished electronic assemblies.

We provide solutions used in semiconductor fabs, electronics manufacturing services (EMS), research labs, and advanced manufacturing facilities.

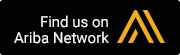

Applied Physics manufactures NIST-traceable contamination wafer standards used to verify the accuracy of scanning surface inspection systems (SSIS), wafer inspection tools, and particle detection equipment.

Our standards use certified polystyrene latex (PSL) microspheres and silica microspheres deposited onto ultra-clean wafers to validate particle sizing accuracy and tool sensitivity.

Capabilities include:

• Spot deposition and full deposition

• 100 mm – 300 mm wafer formats

• Customer wafer processing

• Custom particle distributions

• Tool matching & acceptance testing

• Aerosol particle counter verification

Used for:

• Wafer inspection calibration

• Advanced node contamination monitoring

• Tool qualification & matching

• Process development labs

• Metrology system verification

In addition to metrology standards, Applied Physics supplies complete Surface Mount Technology (SMT) production solutions used to manufacture electronic assemblies for industrial, medical, aerospace, and research applications.

Our equipment portfolio includes:

• Full SMT production lines

• Pick and place machines

• Reflow ovens

• Solder paste printers

• AOI inspection systems

• SPI solder paste inspection systems

• PCB handling conveyors & loaders

• Stencil printers & accessories

• Component feeders and placement heads

• Production support tooling

Applications:

• PCB assembly manufacturing

• Electronics prototyping labs

• Medical device production

• Semiconductor support electronics

• Industrial automation control systems

By combining manufacturing capability with inspection calibration, Applied Physics uniquely supports both building electronic assemblies and validating the environments where they are produced.

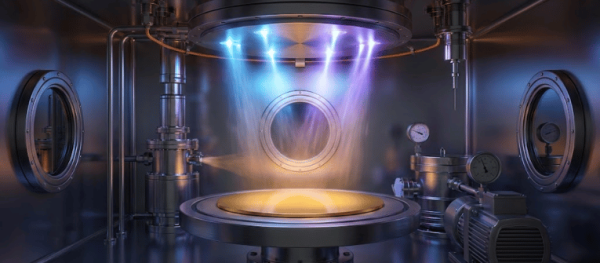

Applied Physics cleanroom foggers are used globally in pharmaceutical manufacturing, sterile compounding pharmacies, semiconductor fabs, hospitals, and research laboratories to visualize airflow patterns and confirm environmental compliance.

Our LN2 foggers produce the highest purity visible vapor available for smoke studies. By combining liquid nitrogen with DI, WFI, or sterile water, the system generates a neutral, residue-free fog ideal for regulated environments.

Used for:

• Aseptic process simulation (APS)

• FDA smoke studies

• ISO cleanroom certification

• Barrier isolators & RABS validation

• Biosafety cabinets (BSC)

• Gloveboxes & sterile suites

Modern features include:

• Adjustable airflow velocity

• Adjustable fog density

• Wireless remote operation

• Rolling trolley design for safety & mobility

Models include AP35 and AP100 ultrapure foggers.

Our portable CRF series foggers (CRF2, CRF3, CRF6) use ultrasonic transducers to generate pure water-based fog for airflow visualization and room balancing.

Ideal for:

• Cleanroom airflow balancing

• Doorway pressure differentials

• Fume hoods & laminar flow benches

• Hospital sterile rooms

• Compounding pharmacies

Features:

• Electro-polished stainless steel enclosures

• DI / WFI / sterile water operation

• Adjustable fog volume & airflow

• Wireless remote control

• Compact portable design

Applied Physics Medical expands our 30+ years of precision engineering into healthcare environments, providing reliable equipment for hospitals, clinics, dental facilities, and laboratories.

Product categories include:

• Hematology analyzers

• Water purification systems

• Sterilization & disinfection equipment

• Laboratory diagnostic instruments

• Infection prevention technologies

Our medical division applies the same contamination-control engineering principles used in semiconductor fabs to clinical environments where reliability and safety are critical.

Applied Physics uniquely serves:

Semiconductor Manufacturing — SMT Process Lines, particle metrology & calibration standards

Pharmaceutical & Cleanroom Validation — airflow visualization & contamination control

Medical & Healthcare Facilities — diagnostic and sterilization equipment

By combining metrology precision with contamination control expertise, we provide solutions that ensure accuracy, compliance, and safety across regulated industries.

Applied Physics is a leading global metrology supplier to pharmaceutical and semiconductor companies. Our products include Cleanroom Foggers, Polystyrene Microspheres, Particle Size Standards, Calibration Wafer Standards, Microbial Air Samplers, Graphene particle products. EPS Polystyrene Puffs are used to fill furniture Poufs, Beanbags, Floor pillows, Throw pillows, Ottomans and more.

Applied Physics has dealers to provide our line of products to their customers.

If your company is interested in becoming an authorized Applied Physics dealer, please click the button below to submit your application.

CRF6: ~2.0 Cubic Meters Fog / Minute, 45 minutes

CRF2: 0.26 Cubic Meters Fog / Minute, 50 minutes

AP35: 5.5+ Cubic Meters Fog / Minute, 60 minutes

PBF-48 using PathAway Decontaminate kills pathogens in Olive Tree growth & improves Dairy production by nearly eliminating pink eye, calf cough and hairy foot wart.

CRF6, Portable Cleanroom Fogger provides adjustable airflow velocity and fog volume control with up to 2.4 cubic meters fog per minute through two 80mm fog outlets for ≈ 45 minutes, ≈ 256.3 ml fog density per minute providing 12 to 15 feet visible airflow using dual 80mm fog outlets. The CRF6 is ideal for smoke studies in clean rooms, ISO suites, sterile rooms, RAB, BSC, barrier isolators, glove boxes, etc. Touch pad control is provided, or optional wireless remote control is available to operate CRF6 behind a closed wall, inside a barrier isolator or glove box. No contamination emitted. The fog evaporates back to air we breathe, no clean room wipe down required. The CRF3 is a smaller version with dual 80mm fog outlet producing 1.2 cubic meters pure fog per minute.

CRF2, Cleanroom Fogger is a low cost fog generator producing 0.26 cubic meters fog per minute through one 60mm fog outlet for ≈ 50 minutes, ≈ 57 ml fog density per minute providing ≈ 6 feet visible fog for smoke studies using deionized, sterilized or WFI water to visualize airflow patterns and turbulence in flow hoods, glove boxes and fume hoods. No contamination emitted, fog evaporates back to air we breathe, no clean room wipe down required. CRF2 Cleanroom Fogger video.

AP35, LN2 Cleanroom Fogger provides adjustable airflow and high volume, adjustable fog output, ≈ 5.5+ cubic meters fog per minute for ≈ 60 minutes, ≈ 571 ml fog density per minute using dual water heater to provide 20 – 30 feet visible fog with 35 L of LN2 + 5 L of (Deionized, Sterile or WFI) water for smoke studies in clean rooms, ISO suites, sterile rooms and medical rooms. Use touch pad control or optional wireless remote control for fogging behind a closed wall. Since 2001 portable cleanroom foggers have provided ultrapure, breathable fog with no clean room wipe down required. AP35 Ultrapure LN2 Fogger video .

Polystyrene Latex Beads, latex spheres, Microspheres and Particle Size Standards are NIST Traceable, certified particle size standards produced as polystyrene microspheres from 20 nm to 160 µm. Polystyrene Latex Microspheres and polystyrene latex spheres are highly accurate, particle size standards with a narrow size distribution, suspended in a DI Water solution with a trace surfactant to minimize agglomeration. Dry Polystyrene particles also available. Polystyrene latex beads are used to create particle aerosol challenge for size calibration of laser particle counters and to produce Calibration Wafer standards.

Silica Microspheres are NIST Traceable, silica calibration particle standards provided from 30 nm to 2500 nm. Silica nanoparticles are used in Pharmaceutical applications and used to deposit Contamination Wafer Standards. Silica CV is typical 3% in size distribution. Silica microspheres are diluted with 15ml ethanol or De-Ionized water, based on customer needs. Dry Silica particles are also available from 100 nm to 2500 nm, from 1 gram to 10 Kg per volume.

Calibration Wafer Standards are certified, NIST traceable, absolute wafer standards deposited with monodisperse, polystyrene latex microspheres at particle diameters of 30 nm to 12 microns. Particle counts deposited are typically between 2000 and 20000 counts on the wafer surface. Spot Depositions can be 1 to 8 particle size peaks deposited around the wafer, depending on the wafer diameter. Calibration Wafer Standards are used to calibrate the size accuracy of scanning surface inspection systems (SSIS), such as Tencor 6200, Tencor 6220, Tencor 6400 and 6420, KLA and Tencor SP1, SP2 and Hitachi wafer inspection tools.

Silica Contamination Wafer Standard are certified, NIST traceable, contamination wafer standards deposited with monodisperse, silica microspheres at particle diameters of 50 nm to 2500 nm ( 2.5 µm). A Silica Contamination Wafer Standard is typically deposited as a full deposition across the wafer; but can be deposited with up to 8 silica size peaks deposited as spot depositions around the wafer standard. Each silica particle size has a narrow size distribution of 3% or less. Silica Contamination Wafer Standards are provided with a NIST Traceable, Size Certificate and are used to calibrate the size accuracy of scanning surface inspection systems (SSIS) using high powered lasers; such as KLA and Tencor SP2, SP3, SP5, SP5xp, KLA and Hitachi wafer inspection tools.

AP100, Ultrapure LN2 Fogger is the highest fog volume, adjustable flow fogger, producing ≈ 15.5 cubic meters ultrapure fog per minute, ≈ 90 minutes operation, ≈ 1520 ml fog density per minute using dual water heaters to provide 30 to 40 feet visible fog using 100 L of LN2 + 10 L of (Deionized, Sterile or WFI) water for smoke studies in large clean rooms, or used to produce large volumes of stage and theatric fog fog. Four fog hose outputs are provided for smoke studies in clean rooms, ISO suites, sterile rooms, medical rooms; and ultrapure fog for theatrical stage fog. Use touch pad control and wireless remote control for operation at a distance. No contamination emitted, fog evaporates back to air we breathe, no clean room wipe down required.

P100 Portable Microbial Air Sampler With its superior functionality and key benefits, the NEW P100 Portable Microbial Air Sampler from Applied Physics is destined to be the industry standard for microbial air sampling. The P100 Microbial Air Sampler offers two CPU controlled sampling rates, 28.3 LPM (1 CFM) and 100 LPM, to allow for continuous monitoring of critical processes, or to take quick cubic meter “grab samples”.

Portable Backpack Dry Fogger, PBDF-48 is a battery operated, backpack, dry fogger with an 8 liter water cavity, which allows mixing with your preferred, water soluble, disinfectant liquid to disinfect your enclosed areas in a rapid manner. The BackPack Fogger operates at 10-15 micron droplet output, making it the only portable Dryfogger with true portability. The Portable Backpack Dry Fogger, PBDF, provides a remote power on switch on the fog hose, so that you can easily turn power on/off as needed. The PBDF allows your trained staff to quickly sanitize rooms, hallways, entry / exit points with your preferred disinfectant, such as Hypochlorous acid anitizing liquid, mixed with pure water at the concentration that you desire in a total of 8 liters liquid. Typical use of the PBDF-48 is to kill dangerous pathogens such as spores, fungii, molds, coronavirus and yeasts such as Candida Auris, a harmful yeast that invades the lungs, blood and brain.

The PBF-48 Portable Backpack Fogger is quite capable of sanitizing rooms and offices using an “All Natural” sterilant, which is capable of killing viruses, coronavirus, spores, molds and fungii on contact. It is most often set up with a 15 micron fog output to support agricultural plant and tree leaf applications; or can be set up with 35 micron fog for surface contact killing of critical unwanted bio-organisms in plant life, such as killing a harmful banana fungus in South America called Tropical Race 4, TP4. The PBF-48 and PBF-24 is used with cattle to mitigate Hairy Foot Warts in dairy and beef cattle, improving beef and dairy production.

The WMF Wall and Table Decontamination Fogger is a truly self-contained unit capable of sanitizing rooms and offices using an “All Natural” sterilant, which is capable of killing viruses, coronavirus, spores, molds and fungii on contact. It is most often set up with a 15 micron fog output to support a dry fog in office or home environments; or can be set up with 35 micron fog for surface contact killing of critical unwanted bio-organisms.

The WMF2 Wall and Table Decontamination Fogger is an upgraded AC unit with a more powerful motor. This unit is ideal for heavier and more continuous use. When used with the all natural solution it is capable of killing viruses, coronavirus, spores, molds and fungii on contact. It is most often set up with a 15 micron fog output to support a dry fog in office or warehouse environments; or can be set up with 35 micron fog for surface contact killing of critical unwanted bio-organisms.

Polystyrene EPS Beads are around 10mm in diameter, about 0.4″, sold by the truckload in plastic bags containing around 50 cubic feet per bag. Puff beads are used to fill furniture Poufs, Beanbags, Throw Pillows, Ottomans and Floor pillows for home/office applications. EPS beads are CFC-free and meet the new RoHS (Restriction of Hazardous Substances).

Cleanroom foggers — including CRF6 Fogger, CRF3 Fogger, DI water foggers, portable cleanroom foggers and LN₂ ultrapure foggers — are used to visualize airflow patterns, turbulence, dead zones, and recovery time in cleanrooms, sterile suites, barrier isolators, RABS, glove boxes and ISO classified environments. These airflow visualization systems support ISO 14644-3 Annex B7 testing, USP <797> in-situ airflow analysis, airflow recovery testing, and semiconductor cleanroom qualification.

The CRF6 and CRF3 portable foggers are among the most widely used airflow visualization tools due to their ability to produce adjustable fog volumes using only WFI, sterile water, or deionized water. The CRF6 generates approximately 2.4 m³/min of fog for mid-range room visualization, while the CRF3 provides approximately 0.89 m³/min for localized airflow verification. The CRF2 offers low-volume visualization for fume hoods and isolators, while the AP35 and AP100 LN₂ ultrapure foggers provide high-volume, long-distance airflow visualization exceeding 30 feet for large cleanrooms and semiconductor production areas. Adjustable airflow velocity, fog density control, and wireless remote operation allow accurate smoke study testing without introducing contamination.

To assist engineers and validation teams, Applied Physics provides a detailed performance comparison resource so users can select the appropriate airflow visualization tool for their validation protocol:

Cleanroom Fogger Comparison Guide

Beyond airflow visualization, Applied Physics manufactures semiconductor metrology standards including calibration wafer standards, contamination wafer standards, PSL particle standards, and silica particle size standards. These NIST traceable standards calibrate surface scanning inspection systems (SSIS), particle counters, wafer scanners and optical inspection tools used in advanced semiconductor manufacturing nodes.

Applied Physics Semiconductor also supplies complete electronics manufacturing systems including automated assembly equipment:

SMT Production Lines & Electronics Manufacturing Equipment

These systems integrate with inspection calibration workflows, allowing facilities to implement both production and metrology qualification from a single engineering partner.

In medical and laboratory environments, Applied Physics Medical provides containment and diagnostic equipment used in clinical diagnostics, research laboratories and sterile processing areas.

Healthcare air protection systems:

Biological Safety Cabinets & Air Protection Equipment

Clinical diagnostic instruments:

Core Laboratory Equipment & Medical Analyzers

These controlled airflow enclosures protect personnel, samples and the environment by maintaining HEPA-filtered laminar airflow and containment during sensitive procedures. Core laboratory equipment supports hematology, diagnostics, and laboratory analysis workflows where contamination control and repeatability are critical.

By combining semiconductor metrology standards, cleanroom airflow visualization, laboratory containment equipment and electronics manufacturing infrastructure, Applied Physics serves pharmaceutical, semiconductor, healthcare and research industries with a unified contamination-control ecosystem designed for validation, production and regulatory compliance.

Understanding the intricate physics behind particle transport through cleanroom door gaps is essential for maintaining stringent ISO classification standards and protecting sensitive processes. Even microscopic openings can serve as conduits

Routine service of a Bio-Safety Cabinet (BSC) such as HEPA filter replacement, motor repairs, or certification is a critical maintenance event. However, it is also a disruptive event. The service

Nitride thin films, such as Titanium Nitride (TiN) and Chromium Nitride (CrN), are essential for extending the lifespan of industrial tools, but achieving maximum hardness requires precise control over the

In a controlled environment, an unplanned power outage or mechanical failure is more than a logistical headache; it is a significant risk to product integrity. When the HVAC system or

In the precise world of semiconductor manufacturing, plasma etch selectivity, the ability to remove a specific material layer while leaving the underlying layer intact,t is paramount. As device nodes shrink

In the pharmaceutical and biopharmaceutical sectors, the sterility of the manufacturing environment is non-negotiable. Barrier isolators and Restricted Access Barrier Systems (RABS) have become the industry standard for aseptic processing,