In the high-stakes world of pharmaceutical manufacturing, biotechnology, and microelectronics, the definition of clean goes far beyond the visible.

While HEPA filters scrub the air and gowning protocols protect against human shedding, the largest surface in any controlled environment, the floor often faces the highest challenge.

The impact of cleanroom floor porosity on microbial control is a critical, yet frequently underestimated, factor in maintaining sterility.

A floor is not just a surface to walk on; it is a contiguous membrane that must resist chemical attack, mechanical load, and, most importantly, microbial colonization.

This article explores the science behind porosity, the risks of biofilm formation, and why selecting the right non-porous substrate is non-negotiable for Good Manufacturing Practice compliance.

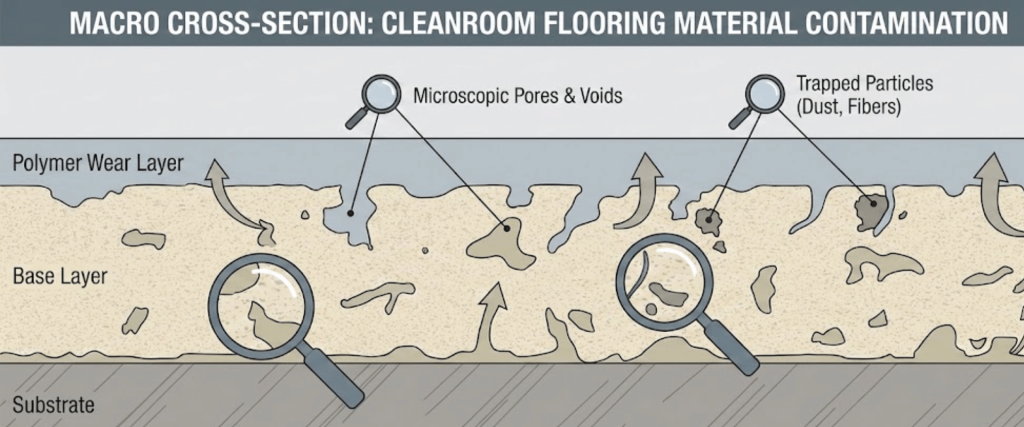

Porosity refers to the measure of void spaces in a material. In the context of flooring, these voids act as microscopic caves.

Even if a floor looks smooth to the naked eye, a high degree of microporosity or surface roughness ($R_a$) can create an environment impossible to disinfect completely.

For effective microbial control, cleanroom flooring must be monolithic, non-porous, and smooth.

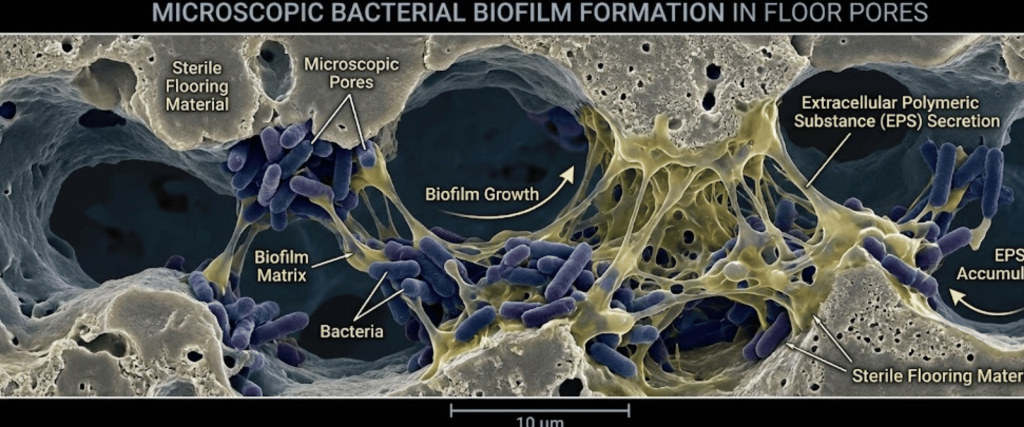

Why is porosity such a threat to cleanrooms? The answer lies in the survival mechanism of bacteria: Biofilms.

When microorganisms find a porous niche such as a crack in an epoxy coating, a pinhole in a vinyl weld, or the natural pores of untreated concrete, they adhere and begin to secrete a slimy extracellular polymeric substance (EPS).

Not all cleanroom floors are created equal. Below is a comparison of common materials based on their porosity and suitability for microbial control.

| Material Type | Porosity Profile | Microbial Control Rating | Notes |

|---|---|---|---|

| Poured Epoxy / Urethane | Non‑Porous (Impervious) | ⭐⭐⭐⭐⭐ | Seamless and monolithic. When applied correctly, it creates a sealed surface with no joints where bacteria can hide. |

| Pharma‑Grade Terrazzo | Non‑Porous (Sealed) | ⭐⭐⭐⭐ | Extremely durable. Requires a high‑quality resin matrix to ensure no micropores exist between aggregates. |

| Vinyl Sheet (Heat Welded) | Low Porosity | ⭐⭐⭐ | The sheet itself is non‑porous, but welded seams are weak points. Over time, seams can crack and create microbial harboring zones. |

| Polished Concrete | High Porosity | ⭐ | Not suitable for sterile areas. Even with densifiers, it retains capillary pores that can trap moisture and microbes. |

| Rubber | Low Porosity | ⭐⭐ | Often sensitive to harsh disinfectants (phenolics and sporicidals), which can degrade the surface and increase porosity over time. |

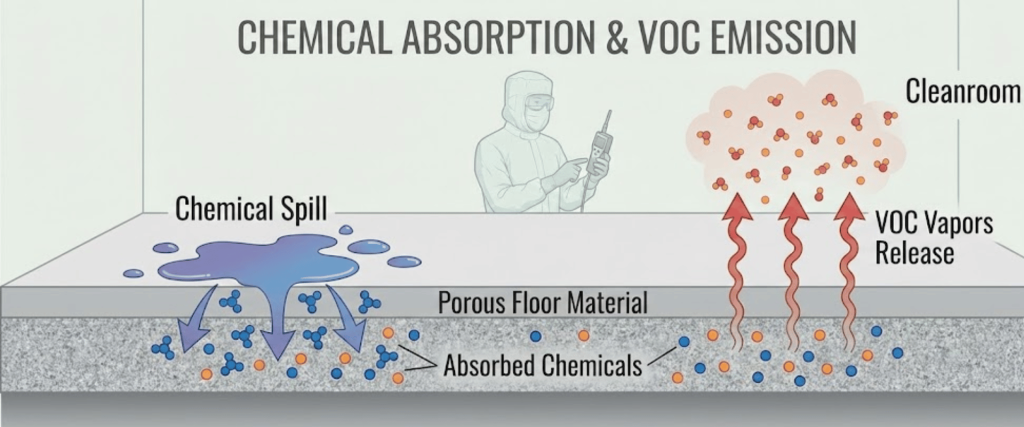

The efficacy of your cleaning protocol is directly tied to the substrate. If you are using expensive sporicidal agents on a porous floor, you are likely wasting money.

Regulatory bodies like the FDA and EMA strictly audit facility finishes.

To maintain a state of control, facility managers must view the floor as a critical component of their sterility assurance strategy.

The impact of cleanroom floor porosity on microbial control is undeniable: porosity equals risk.

Porous floors soak up disinfectants, preventing the required wet contact time needed to kill germs. Microbes hiding inside pores remain untouched by the chemical.

While vinyl is low-porosity, its welded seams often crack over time. Seamless epoxy creates a single, unbroken layer that leaves zero harboring zones for bacteria.

Yes. Standard cleaning only hits the surface. If the floor is porous, bacteria stay alive inside the substrate, forming biofilms that lead to persistent contamination.

Since 1992, Applied Physics Corporation has been a leading global provider of precision contamination control and metrology standards. We specialize in airflow visualization, particle size standards, and cleanroom decontamination solutions for critical environments.