Maintaining a sterile environment is the cornerstone of successful laboratory work, whether you’re involved in tissue culture, microbiology, or semiconductor assembly. At the heart of this sterility lies the Laminar Flow Hood (LFH).

However, a laminar flow hood is not a set it and forget it tool. Its effectiveness relies on a delicate balance of physics and disciplined maintenance.

This article dives into the science behind keeping your hood operational and your workspace uncontaminated.

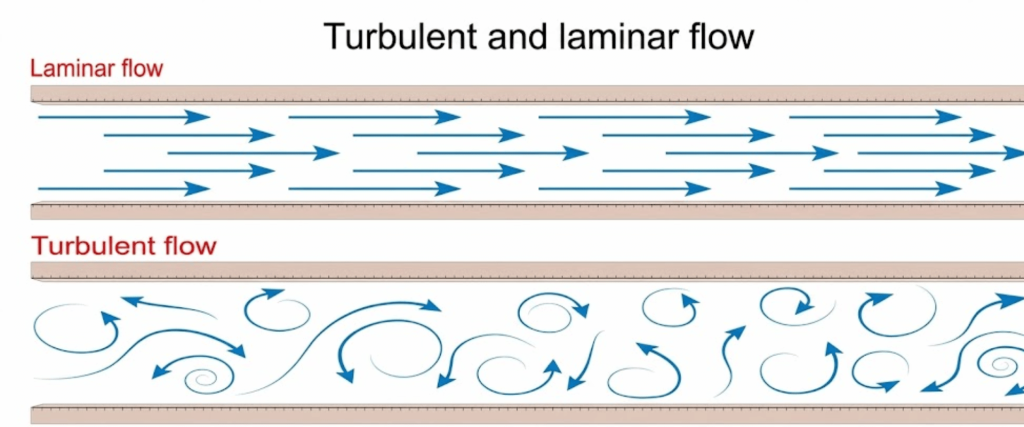

To maintain a hood, you must first understand its mechanism. Unlike turbulent flow, where air moves in unpredictable swirls, laminar flow consists of air moving at a constant speed and direction in parallel layers.

This sweep of air ensures that any particulates generated within the workspace are immediately pushed out, preventing them from settling on your samples.

The most common source of contamination isn’t the machine; it’s the operator. Daily care focuses on maintaining the clean zone.

The HEPA filter is a dense mat of randomly arranged fibers. Over time, these fibers trap particles, increasing resistance.

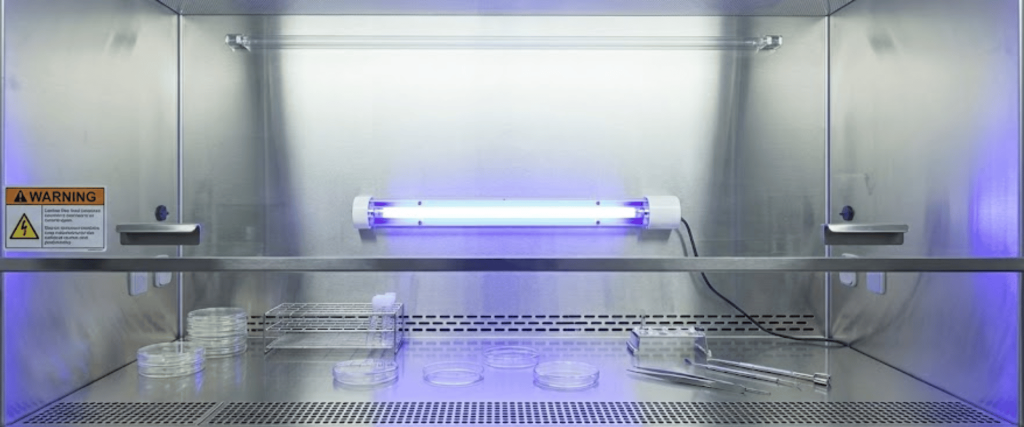

Many hoods use UV-C lamps ($254 \text{ nm}$ wavelength) to denature the DNA of microorganisms. However, UV lamps are deceptive.

While daily cleaning is up to you, the Science of Care requires professional verification at least once or twice a year.

| Test Type | Purpose |

|---|---|

| Integrity Test (DOP) | Uses aerosolized smoke to check for small leaks in the HEPA filter. |

| Airflow Visualization | Uses smoke sticks to confirm that air moves in straight, parallel lines without turbulence. |

| Particle Counting | Uses a laser particle counter to verify that the hood meets ISO Class 5 standards. |

Maintaining a laminar flow hood is an exercise in precision. It is not merely about keeping a surface clean; it is about preserving the aerodynamic integrity that protects your research, your product, and your reputation.

By understanding the physics of airflow and the lifespan of HEPA filtration, you transform a simple piece of equipment into a reliable fortress against contamination. Consistent care doesn’t just prevent failed experiments, it extends the life of your expensive hardware and ensures that every minute spent at the bench is backed by scientific certainty.

Under normal laboratory conditions, a HEPA filter typically lasts between 3 and 5 years. However, this depends heavily on how often the pre-filters are changed and the cleanliness of the surrounding room. If the airflow velocity drops below $90 \text{ fpm}$ even after the pre-filters are replaced, it is time for a new HEPA filter.

No. A standard horizontal or vertical laminar flow hood is designed to protect the product, not the user. Because the air is blown from the filter across the workspace and directly toward the operator, working with biohazards or volatile chemicals would expose you to those materials. For hazardous work, you must use a Class II Biosafety Cabinet (BSC).

It sounds counterintuitive, but 70% IPA is more effective at killing microbes than 99%. The 30% water content slows down evaporation and helps the alcohol penetrate the cell walls of bacteria and fungi. 99% alcohol evaporates too quickly and often causes the external proteins of a microbe to coagulate, creating a protective shell rather than killing it.

Since 1992, Applied Physics Corporation has been a leading global provider of precision contamination control and metrology standards. We specialize in airflow visualization, particle size standards, and cleanroom decontamination solutions for critical environments.