In industries ranging from semiconductor manufacturing to high-end theatrical production, the quality of fog is rarely about just making smoke; it is about density, control, and retention.

Choosing between a Liquid Nitrogen (LN2) Fogger and an Ultrasonic Fogger often comes down to physics.

This article investigates the mechanisms behind these technologies, specifically analyzing how they generate fog and, crucially, how well they retain that fog density over time and distance.

To understand density retention, we must first understand the thermodynamic origin of the fog in each system.

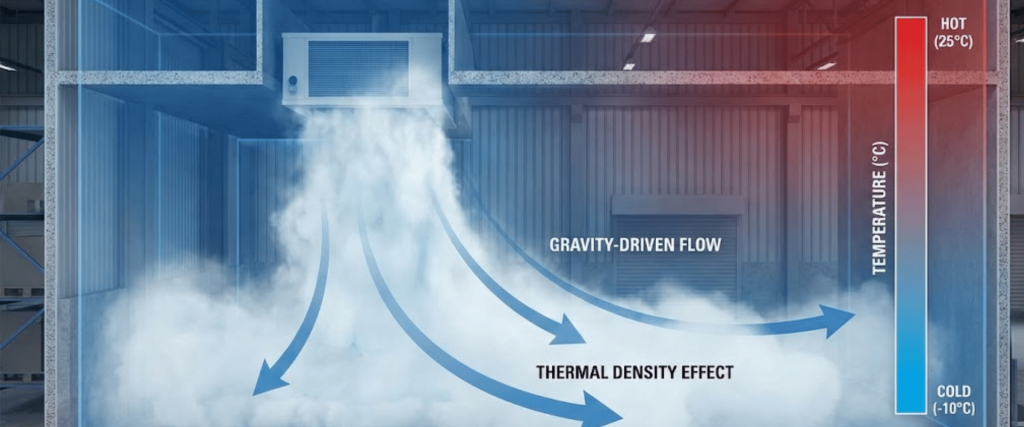

LN2 foggers operate on the principle of extreme temperature differentials.

Liquid nitrogen is stored at approximately -196°C (-320°F). When this cryogenic liquid meets water (or ambient air), it causes rapid condensation of water vapor.

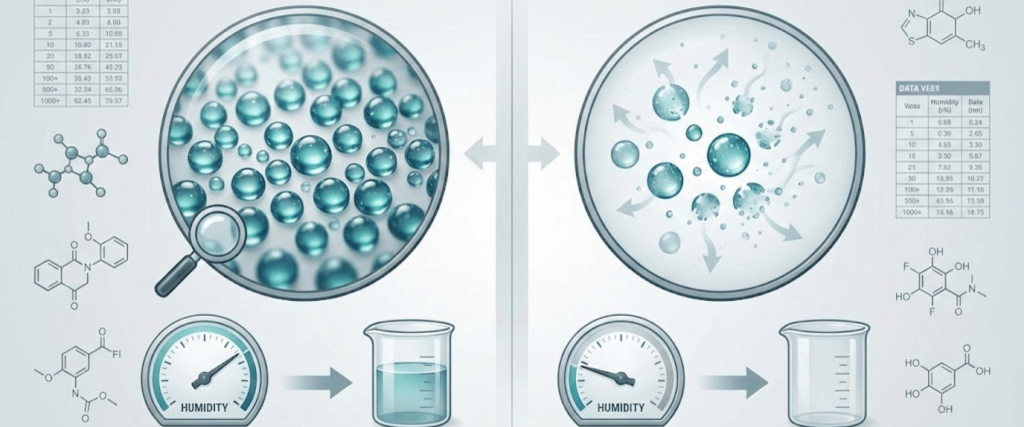

Ultrasonic foggers do not rely on heat or cold. Instead, they use high-frequency mechanical vibrations.

Retention refers to two characteristics. Opacity (how thick the white cloud remains) and Spatial Structure (how well the fog holds its shape against airflow or diffusion).

This is the primary differentiator.

The following table contrasts the behavior of the two systems in a controlled environment (20°C, 50% RH).

| Feature | Nitrogen-Based (LN₂) Fogger | Ultrasonic (DI Water) Fogger |

|---|---|---|

| Fog Density | Extremely high; looks like a solid, opaque white wall | Medium to high; can be translucent to opaque depending on number of transducers |

| Retention Profile | Stays close to the floor; keeps density while flowing over surfaces | Stays airborne; moves with airflow and thins out as it spreads |

| Dissipation | Evaporates cleanly with no residue | Evaporates; may leave water residue if air becomes saturated |

| Travel Distance | Can move 20–30 feet while staying visibly dense | Usually spreads or fades within 3–6 feet without fan support |

| Fluid Consumption | High (liquid nitrogen plus water) | Low (deionized water only) |

While both technologies create visible mist, they serve opposite physics.

If your goal is maximum density retention over distance and a strictly controlled, low-lying visual profile, Nitrogen-Based Foggers are the superior choice.

Their high thermal density prevents the fog from diffusing into the ambient air, keeping the visual effect tight and opaque.

If your goal is cost-effective misting, local humidity control, or short-range visualization where heavy sinking is undesirable, Ultrasonic Foggers provide a continuous, ambient-temperature solution.

Liquid Nitrogen (LN2) foggers create a significantly denser and whiter cloud. Because the fog is extremely cold, the droplets are packed tightly together, creating an opaque wall of white fog that is much thicker than the mist from ultrasonic units.

Yes, they can. Since ultrasonic foggers spray microscopic water droplets at room temperature, these droplets can settle on surfaces and create dampness. In contrast, nitrogen fog evaporates completely and leaves no residue, making it safer for electronics and cleanrooms.

It comes down to physics. The nitrogen gas is colder than the room’s air, making it heavier. This extra weight pulls the fog down to the floor (the blanket effect), whereas ultrasonic fog is the same temperature as the air and floats away easily.

Since 1992, Applied Physics Corporation has been a leading global provider of precision contamination control and metrology standards. We specialize in airflow visualization, particle size standards, and cleanroom decontamination solutions for critical environments.