In today’s rapidly changing industrial environment, the demand for precision, compliance, and operational efficiency has increased more than ever.

Video monitoring systems are at the center of this change, and the arrival of 4K Digital Video Recorders (DVRs) has set new standards for clarity, analytics, and reliability.

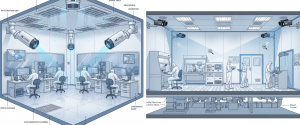

Our 4K Digital Video Recorder stands out as a cutting-edge solution, specifically designed for industrial monitoring and cleanroom analysis. This article examines how 4K DVRs are transforming these fields.

A 4K Digital Video Recorder (DVR) is a device that captures, stores, and manages ultra-high-definition (UHD) video footage typically at a resolution of 3840 x 2160 pixels.

In industrial and cleanroom environments, this level of detail is essential for monitoring processes, ensuring compliance, and supporting advanced analytics. Our 4K DVR is engineered for demanding environments, delivering robust performance, reliability, and integration with other facility management systems.

Particle and Contamination Detection 4K video enables the identification of minute particles and subtle procedural deviations, which are critical for maintaining cleanroom standards in pharmaceuticals, biotechnology, and semiconductor manufacturing.

Media Fill and Aseptic Process Validation High-definition video documentation supports root cause analysis and regulatory audits, ensuring that all processes meet stringent industry standards.

Immersive Training Tools 4K recordings are used to create detailed training materials and VR-based simulations, helping to standardize procedures and reduce human error.

Continuous Surveillance Corrosion-resistant 4K cameras provide uninterrupted monitoring, supporting both security and quality assurance without compromising cleanroom sterility.

| Feature | Details/Implications |

|---|---|

| Resolution | 4K UHD (3840 x 2160 pixels) |

| Channel Capacity | 8, 16, or 32 channels for multi-camera setups |

| Storage | Up to 80TB with security-grade hard drives |

| Compression | H.265/HEVC for efficient storage |

| Remote Access | Web, mobile app, and desktop software |

| AI Analytics | Motion, object, and event detection |

| Environmental Durability | Industrial/laboratory grade build |

| Integration | Compatible with facility management and control systems |

We 4K Digital Video Recorder exemplifies the next generation of industrial monitoring and cleanroom analysis tools.

By delivering ultra-high-definition video, advanced analytics, and robust integration capabilities, it empowers organizations to achieve higher productivity, enhanced compliance, and superior operational insight.

As industries continue to demand greater precision and accountability, 4K DVRs are not just a technological upgrade; they are a strategic investment in quality, safety, and efficiency.

Yes, 4K DVRs are highly suitable for industrial and cleanroom monitoring. Their ultra-high-definition video quality allows you to capture even the smallest details, which is essential for process monitoring, compliance, and security. This makes it easier to review incidents and perform detailed analysis.

The 4K DVR from Applied Physics USA can be used in industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, aerospace, and research laboratories. It is especially useful in environments where contamination control, process validation, or security monitoring is required.

Absolutely, the Applied Physics USA 4K DVR supports both remote monitoring and AI-based analytics. You can view real-time video from anywhere and use smart features like motion detection, object tracking, and event-based recording, making facility management easier and more effective.

Since 1992, Applied Physics Corporation has been a leading global provider of precision contamination control and metrology standards. We specialize in airflow visualization, particle size standards, and cleanroom decontamination solutions for critical environments.