The semiconductor industry is at a pivotal turning point. As we move into 2026, the limitations of traditional Silicon (Si) have become more apparent, especially with the explosion of Generative AI, Electric Vehicles (EVs), and 6G technology.

To meet the demands of higher power, faster switching, and extreme thermal management, researchers and manufacturers are shifting toward Wide Bandgap (WBG) and 2D materials.

For industry leaders, staying ahead means understanding these materials and the precision metrology required to manufacture them.

Gallium Nitride continues to dominate the power electronics conversation in 2026. While it started in fast chargers for smartphones, its role has expanded into AI data centers and 5G/6G infrastructure.

![]()

Why it’s trending: GaN allows for much higher electron mobility than silicon, meaning devices can switch faster and stay cooler.

The 2026 Outlook: We are seeing a massive shift toward GaN-on-Silicon 12-inch wafers, which is significantly driving down production costs.

Manufacturing Tip: Due to the complex epitaxial growth of GaN, surface contamination is a major risk. Using NIST-traceable Wafer Standards is critical for calibrating inspection systems to detect defects early.

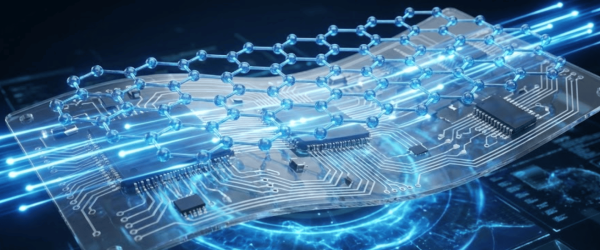

Graphene, a single layer of carbon atoms arranged in a two-dimensional lattice, has garnered significant attention since its discovery due to its remarkable electrical, thermal, and mechanical properties.

With an electron mobility that surpasses that of silicon by orders of magnitude, graphene is poised to revolutionize high-speed electronics. Its ability to conduct electricity with minimal resistance makes it an ideal candidate for applications in transistors, sensors, and high-frequency devices.

Moreover, graphene’s flexibility and lightweight nature open up new possibilities for wearable technology and flexible electronics. Researchers are investigating its use in transparent conductive films for touchscreens and displays, as well as in advanced batteries that require lightweight materials with high conductivity.

As production techniques improve and costs decrease, graphene could become a cornerstone material in next-generation semiconductor devices, enabling faster and more efficient electronic systems.

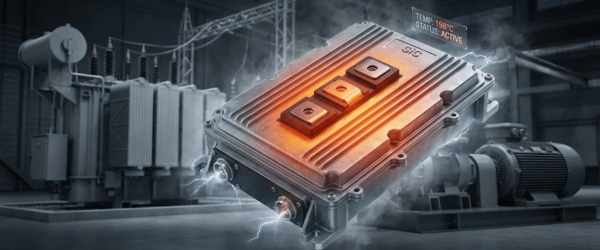

If GaN is the king of frequency, Silicon Carbide is the king of power. By 2026, SiC has become the standard for Electric Vehicle traction inverters.

Why it’s trending: SiC can operate at much higher voltages and temperatures (up to 200°C+) compared to silicon. This translates to longer battery range and faster charging times for EVs.

The 2026 Outlook: The industry is transitioning from 6-inch to 8-inch (200mm) SiC wafers to increase yield.

Precision Requirement: High-power SiC devices are prone to stacking faults. Monitoring airflow patterns in the fab using Cleanroom Foggers ensures that the ultra-clean environment necessary for SiC crystal growth remains uncompromised.

| Metrics | Perovskite Solar Cells | Perovskite LEDs |

|---|---|---|

| Efficiency | Over 25% | High quantum efficiency |

| Cost | Low production cost | Cost-effective |

| Flexibility | Flexible and lightweight | Flexible and customizable |

| Stability | Improving stability | Enhanced stability |

Silicon carbide (SiC) is another emerging semiconductor material that has garnered attention for its ability to operate under extreme conditions.

With a wide bandgap and excellent thermal conductivity, SiC is particularly well-suited for high-power applications such as electric vehicles, industrial motor drives, and power grid systems. Its robustness allows devices made from SiC to function efficiently at higher voltages and temperatures than their silicon counterparts.

The automotive industry is one of the primary beneficiaries of SiC technology. Electric vehicles equipped with SiC power electronics can achieve greater range and efficiency due to reduced energy losses during power conversion. Additionally, SiC’s ability to withstand harsh environments makes it ideal for aerospace and military applications where reliability is paramount.

Organic semiconductors represent a unique class of materials that offer flexibility and lightweight characteristics not found in traditional inorganic semiconductors.

Composed of carbon-based molecules, these materials can be processed at low temperatures and printed onto various substrates, making them ideal for applications in flexible electronics such as organic light-emitting diodes (OLEDs), organic solar cells, and flexible displays.

Recent advancements in organic semiconductor technology have led to significant improvements in performance metrics such as charge mobility and stability.

Companies are increasingly investing in organic electronics due to their potential for low-cost manufacturing and versatility in design. For instance, OLED displays have already transformed the television and smartphone markets with their vibrant colors and thin profiles.

As research continues to push the boundaries of organic semiconductors, we can expect further innovations that will enhance user experiences across a range of electronic devices.

For decades, Silicon has been the gold standard of the electronics world. However, as we approach 2026, we are hitting what experts call the Silicon Ceiling. The physical limits of silicon mean it can no longer keep up with the extreme heat and speed requirements of Generative AI and 6G telecommunications.

![]()

The future is no longer about just making chips smaller; it’s about making them smarter and more resilient. This shift is defined by three major pillars:

Energy Decarbonization: With the global push for Net-Zero, materials like SiC (Silicon Carbide) are becoming essential for reducing energy loss in power grids and EVs.

The AI Explosion: AI data centers now consume massive amounts of power. Future materials must handle higher power density without melting.

Heterogeneous Integration: 2026 is the year of Chiplets. Instead of one giant chip, manufacturers are stacking different materials (like GaN on Silicon) to get the best of both worlds.

As we move toward these advanced materials, the manufacturing process becomes incredibly sensitive. Traditional inspection isn’t enough. Next-gen materials require NIST-traceable calibration standards to ensure that atomic-level defects don’t ruin a multi-million dollar wafer batch. This is where precision metrology tools, such as those provided by US, become the silent enablers of this technological revolution.

As we look toward 2026, the transition from silicon to advanced materials like GaN and SiC is no longer optional but a necessity for the next generation of AI and green energy.

These innovations demand unprecedented levels of purity and precision in the manufacturing environment to ensure high yields and device reliability.

By leveraging cutting-edge metrology and contamination control, industries can successfully navigate the complexities of these ultra-wide bandgap materials.

Applied Physics USA remains committed to providing the calibration standards and airflow visualization tools required for this critical technological leap. Ultimately, the future of semiconductors relies as much on the materials themselves as it does on the precision of their fabrication.

While Silicon has been the industry standard for decades, it is reaching its physical limits regarding heat tolerance and switching speeds. In 2026, applications like 6G, AI data centers, and long-range Electric Vehicles require materials that can operate at much higher voltages and frequencies with minimal energy loss, which Silicon cannot sustain.

Gallium Nitride offers significantly higher electron mobility and a wider bandgap compared to Silicon. This allows for the creation of smaller, faster, and more efficient power converters. In practical terms, this means faster charging for consumer electronics and reduced cooling costs for massive AI server farms.

Newer semiconductor materials are highly sensitive to crystal defects and surface contamination. Precision metrology, including the use of NIST-traceable wafer standards, is essential to calibrate the inspection systems that detect these flaws. Without accurate maaping (measurement), the production yield for these expensive materials would be too low for commercial viability.

While GaN and SiC are the current leaders, Gallium Oxide ($Ga_2O_3$) and Diamond Semiconductors are the most promising for the long-term future. These materials offer extreme thermal conductivity and breakdown fields, making them ideal for deep-space exploration, advanced military hardware, and the next evolution of the global power grid.

Since 1992, Applied Physics Corporation has been a leading global provider of precision contamination control and metrology standards. We specialize in airflow visualization, particle size standards, and cleanroom decontamination solutions for critical environments.