Retrofitting HVAC systems in cleanroom environments is a significant investment aimed at improving air quality, energy efficiency, and regulatory compliance.

However, the true measure of success lies in the system’s ability to maintain stringent environmental controls post-retrofit.

Facility managers and HVAC professionals must validate that the upgraded system meets cleanroom standards, prevents contamination, and supports operational goals.

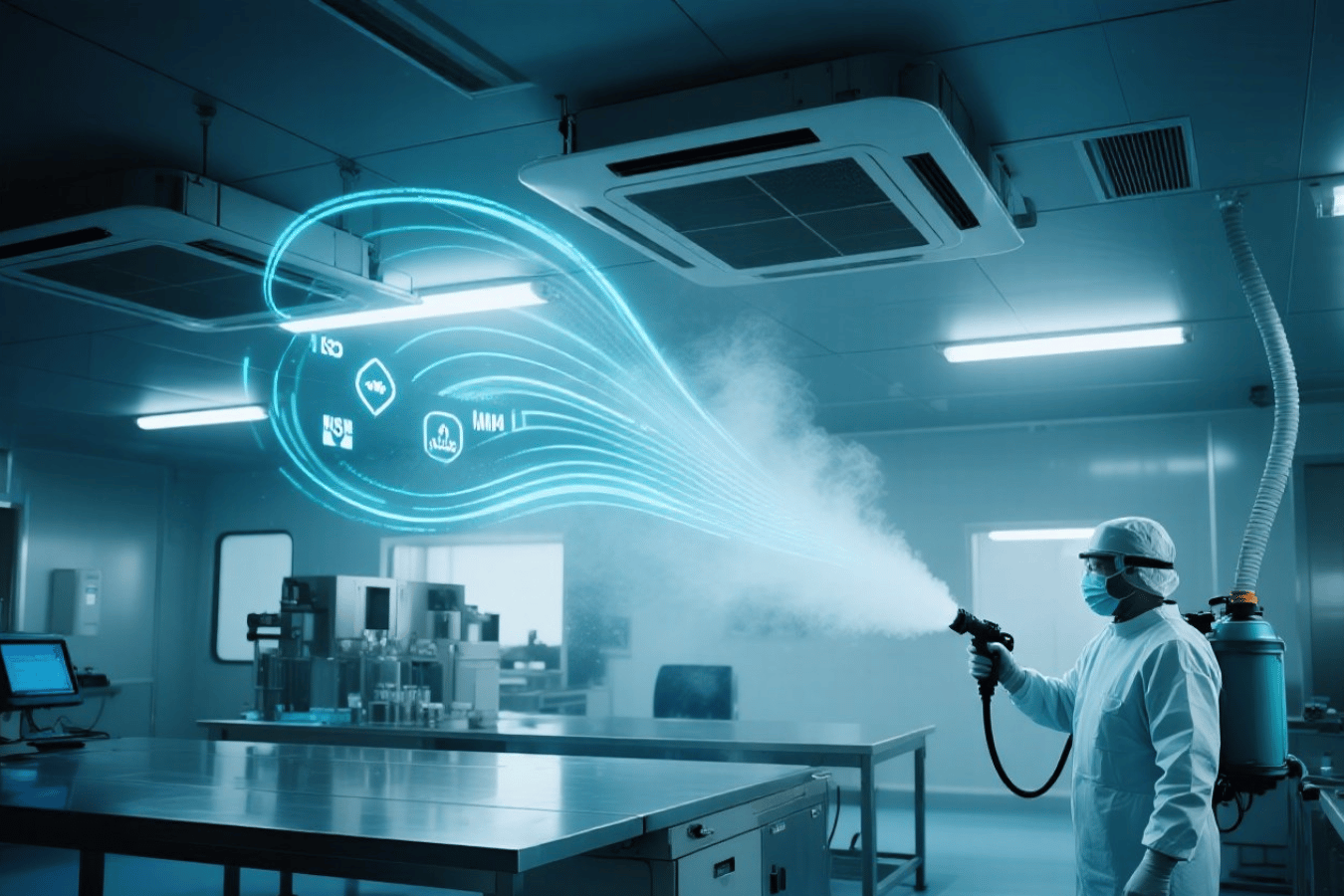

Cleanroom foggers have emerged as a critical tool for this validation, providing a visual and data-driven method to assess airflow patterns and system performance.

Why Use Foggers for HVAC Retrofit Validation?

After an HVAC retrofit, it’s essential to confirm that the system delivers the required airflow patterns and maintains cleanroom integrity. Foggers provide immediate visual feedback that helps:

- Verify laminar or unidirectional airflow: Critical for contamination control in key zones.

- Detect turbulence, dead zones, or reverse flows: These can affect product quality and regulatory compliance.

- Support documentation and compliance: Visual records from fogger tests are valuable for audits and ongoing monitoring.

Using foggers is a best practice recommended by ISO 14644-3 and Good Manufacturing Practice (GMP) guidelines for cleanroom validation.

Using Foggers to Assess HVAC Retrofit Success

1) Preparation

- Review retrofit objectives and cleanroom classification (ISO 5, 7, 8, etc.).

- Select the appropriate fogger based on room size and sensitivity.

- Ensure all personnel are trained in fogger operation and safety protocols.

2) Set Up the Test Environment

- Seal off non-essential areas to prevent fog migration.

- Position the fogger at critical points (e.g., near HEPA filters, air returns, or process equipment).

- Set up video recording and adequate lighting for documentation.

3) Conduct Airflow Visualization

- Activate the fogger and observe the movement of fog:

- Laminar flow: Fog should move in parallel streams with minimal turbulence.

- Turbulence or dead zones: Look for swirling, stagnant, or reverse-flow areas.

- Direct fog into ductwork or across filter faces to check for leaks or bypass.

4) Record and Analyze Results

- Document findings with video and written notes.

- Compare observed airflow patterns to design specifications and regulatory requirements.

- Identify and address any issues (e.g., leaks, improper balancing, or insufficient coverage).

5) Report and Validate

- Compile a comprehensive report: including visual evidence, test conditions, and corrective actions.

- Use results for regulatory certification: (ISO 14644, FDA, GMP) and internal quality assurance.

Types of Cleanroom Foggers for HVAC Testing

1) DI Water Foggers

- Medium: Deionized water

- Features: Produces pure, residue-free fog; ideal for sensitive environments

- Typical Output: 0.7–2.0 m³/min; visual distance up to 15 feet

- Best For: Small to medium cleanrooms, routine validation.

2) LN2-DI Water Foggers

- Medium: Liquid nitrogen and deionized water

- Features: High-density, ultra-pure fog; adjustable volume and velocity

- Typical Output: 5–24 m³/min; visual distance up to 25 feet

- Best For: Large cleanrooms, HVAC system commissioning, and retrofits.

3) Glycol-Based Foggers

- Medium: Glycol solution

- Features: Longer fog duration; may leave residue

- Best For: Extended studies where residue is not a concern.

4) CO₂ Foggers

- Medium: Dry ice and water

- Features: Quick, simple checks; heavier-than-air fog

- Best For: Non-critical, rapid assessments.

Tip: For HVAC retrofit validation, LN2-DI water foggers are often preferred due to their high output, neutral buoyancy, and residue-free operation.

Key Success Metrics for HVAC Retrofits

- Air Quality: Achieving required particle counts and cleanliness levels (ISO class compliance)

- Airflow Patterns: Consistent, unidirectional flow with no turbulence or dead zones

- Temperature and Humidity Stability: Maintaining tight control within specified tolerances

- Pressure Differentials: Correct positive or negative pressure relationships between zones

- System Reliability: Minimal downtime and consistent performance post-retrofit

- Regulatory Compliance: Successful validation and certification to ISO, FDA, or cGMP standards

- Documentation: Complete records of testing, commissioning, and maintenance.

Common Challenges and How to Overcome Them

| Focus Area |

Actionable Guidance |

| Integrating with Existing Infrastructure |

Use modular foggers and run phased testing to fit space and operational constraints. |

| Maintaining Environmental Controls During Testing |

Set up temporary barriers and apply environmental controls to prevent contamination. |

| Managing Regulatory and Compliance Risks |

Document all procedures and results thoroughly; resolve any deviations immediately. |

| Procurement Planning and Lead Times |

Plan early for specialized fogger equipment and accessories to avoid delays. |

| Cross‑Stakeholder Communication |

Keep clear, consistent communication among facility managers, HVAC professionals, and regulatory bodies throughout the process. |

Best Practices and Industry Standards

- Follow ISO 14644-3 for airflow visualization and cleanroom testing protocols.

- Adhere to GMP guidelines for documentation, risk assessment, and validation.

- Use a written program outlining test scope, methods, acceptance criteria, and corrective actions.

- Train personnel on contamination control, proper gowning, and cleanroom behavior.

- Regularly requalify and monitor cleanroom performance to ensure ongoing compliance.

Conclusion

Assessing HVAC retrofit success in cleanrooms is a multi-faceted process that demands rigorous validation, clear documentation, and adherence to industry standards.

Cleanroom foggers are indispensable tools for visualizing airflow, detecting issues, and providing the evidence needed for regulatory compliance.

By following best practices and leveraging the right fogger technology, facility managers and HVAC professionals can ensure that retrofitted systems deliver optimal performance, protect product quality, and meet the highest standards of cleanroom operation.

Ready to validate your next HVAC retrofit?

Choose the right cleanroom fogger, follow a structured assessment process, and ensure your cleanroom meets every standard today and into the future.

Frequently Asked Questions (FAQs)

1. What is a cleanroom fogger, and what is it used for?

A cleanroom fogger is a device that produces clean, residue-free fog. It is used in cleanrooms or controlled environments to visualize airflow, detect leaks, and check the performance of HVAC systems.

2. Why is it important to use a fogger after an HVAC retrofit?

After an HVAC retrofit, a fogger is used to visualize airflow patterns. This helps determine whether the new system is working properly, if there is any turbulence, dead zones, or leaks, and whether the system meets required standards.

3. Which foggers are best for HVAC testing?

For HVAC testing, DI water foggers, LN2-DI water foggers, and sometimes glycol-based foggers are commonly used. LN2-DI water foggers are considered best for large cleanrooms and retrofit validation because they produce a high output and residue-free fog.