Designing a cleanroom is one thing. Proving it performs according to ISO 14644-3 test methods is another. From airborne particle counting to airflow visualization studies, ISO 14644-3 ensures facilities meet their classification and regulatory expectations.

Airborne Particle Counts: Calibrated using PSL standards.

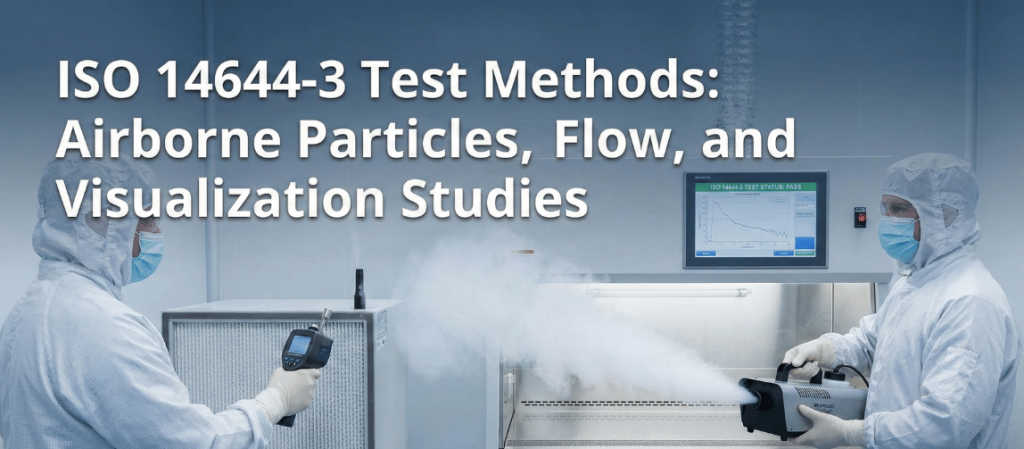

Airflow Visualization: Conducted with ultrapure foggers.

Recovery Time Tests: How quickly particle counts return to baseline.

Containment Tests: Ensuring no leaks between pressure cascades.

ISO 14644-3: Defines test methods and frequency.

EU GMP Annex 1: Requires smoke studies in Grade A/B zones.

FDA Guidance: Expects particle data traceable to NIST standards.

CRF Cleanroom Foggers: Dense, ultrapure fog for airflow visualization.

AP100 LN₂ Fogger: Long-duration fog for pharma smoke studies.

PSL Particle Standards: Calibration of particle counters.

Calibration Wafers: Semiconductor-specific particle validation.

Particle counting in ISO 3–5 zones.

Fog visualization for wafer transfer systems.

Annex 1 requires full video documentation of smoke studies.

Recovery and containment tests performed routinely.

ISO 7–8 particle monitoring for packaging lines.

Traceability of particle counts via PSL standards.

ISO 14644-3 is the backbone of cleanroom validation. From fog visualization to PSL calibration, it ensures facilities don’t just meet design intent—they prove it. Applied Physics provides the tools to meet every requirement.

Since 1992, Applied Physics Corporation has been a leading global provider of precision contamination control and metrology standards. We specialize in airflow visualization, particle size standards, and cleanroom decontamination solutions for critical environments.