In industries where contamination control is mission-critical, such as pharmaceuticals, biotechnology, medical device manufacturing, and advanced electronics, cleanroom technology is the backbone of quality and compliance.

As the demand for flexible, scalable, and efficient cleanroom solutions continues to grow, modular cleanroom designs supported by portable foggers are rapidly becoming the gold standard.

This article explains how our innovative fogger technology, when integrated with modular cleanrooms, delivers unmatched performance, compliance, and operational efficiency.

A modular cleanroom is a controlled environment constructed from prefabricated, pre-engineered components that are assembled on-site. Unlike traditional stick-built cleanrooms, modular systems are designed for rapid deployment, scalability, and adaptability.

They can be installed as freestanding structures within existing facilities and are available in various ISO classifications to meet specific cleanliness requirements.

Portable foggers are advanced devices that generate ultra-fine, ultrapure fog using ultrasonic or piezoelectric technology. In cleanroom settings, they serve two primary purposes:

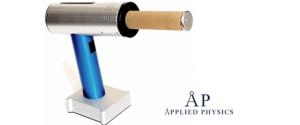

We are a leader in cleanroom fogging solutions, offering models such as the AP35, AP100, CRF2, and CRF4. These foggers are engineered for:

Portable foggers can be quickly deployed within modular cleanrooms to provide an extra layer of contamination control. The ultra-fine mist ensures that all surfaces, including hard-to-reach areas, are disinfected, reducing the risk of microbial contamination.

Modular cleanrooms are designed for rapid deployment and reconfiguration. Portable foggers complement this by enabling fast, on-demand decontamination crucial for temporary setups, emergency operations, or when transitioning between production batches.

Foggers support compliance with ISO 14644, FDA cGMP, and GMP standards by providing a validated method for environmental decontamination and supporting cleanroom validation protocols. They can be integrated into routine cleaning and validation schedules, ensuring consistent performance and documentation for audits.

Both modular cleanrooms and portable foggers are designed to minimize downtime. Foggers reduce the time required for manual cleaning, while modular cleanrooms can be quickly reconfigured or expanded as needed, leading to lower operational costs and higher productivity.

As operations grow or change, modular cleanrooms can be expanded or reconfigured. Portable foggers can be easily moved and used in new or reconfigured spaces, maintaining consistent contamination control across all areas.

| Type of Modular Cleanroom | Description |

|---|---|

| Hardwall Modular Cleanrooms | Rigid, durable panels for high-level contamination control. |

| Softwall Modular Cleanrooms | Flexible vinyl curtains for quick setup and reconfiguration. |

| Hybrid Modular Cleanrooms | Combine hardwall and softwall elements for tailored solutions. |

| Specialized Modular Cleanrooms | Designed for unique applications like dry rooms or data centers. |

Portable foggers play a critical role in meeting these standards by supporting airflow visualization, leak detection, and validated decontamination processes.

Explore our modular cleanroom and portable fogger solutions today to achieve the highest standards of cleanliness, compliance, and operational efficiency.

Modular cleanroom design supported by portable foggers represents the next generation of contamination control, combining flexibility, scalability, and validated performance.

We advanced fogger technology, when integrated with modular cleanrooms, delivers superior environmental control, rapid deployment, and ongoing compliance with the world’s most stringent standards.

Whether you are scaling up pharmaceutical production, launching a biotech startup, or responding to emergency healthcare needs, this powerful combination ensures your cleanroom environment is always one step ahead.

Hardwall modular cleanrooms use rigid and durable panels, making them more effective for contamination control. Softwall modular cleanrooms are made with flexible vinyl curtains, which make them easy to set up and reconfigure as needed.

Hybrid modular cleanrooms are used when a facility needs both the durability of hardwalls and the flexibility of softwalls. They offer tailored solutions to meet specific requirements.

Since 1992, Applied Physics Corporation has been a leading global provider of precision contamination control and metrology standards. We specialize in airflow visualization, particle size standards, and cleanroom decontamination solutions for critical environments.