Animal research laboratories, veterinary hospitals, and breeding facilities require thorough cage cleaning to ensure animal health and the accuracy of experimental results.

Choosing between using an automatic animal cage washer and cleaning cages manually is very important for maintaining hygiene standards, reducing staff workload, and improving facility workflow.

This article examines both methods in detail, comparing their effectiveness, cost, efficiency, and long-term benefits.

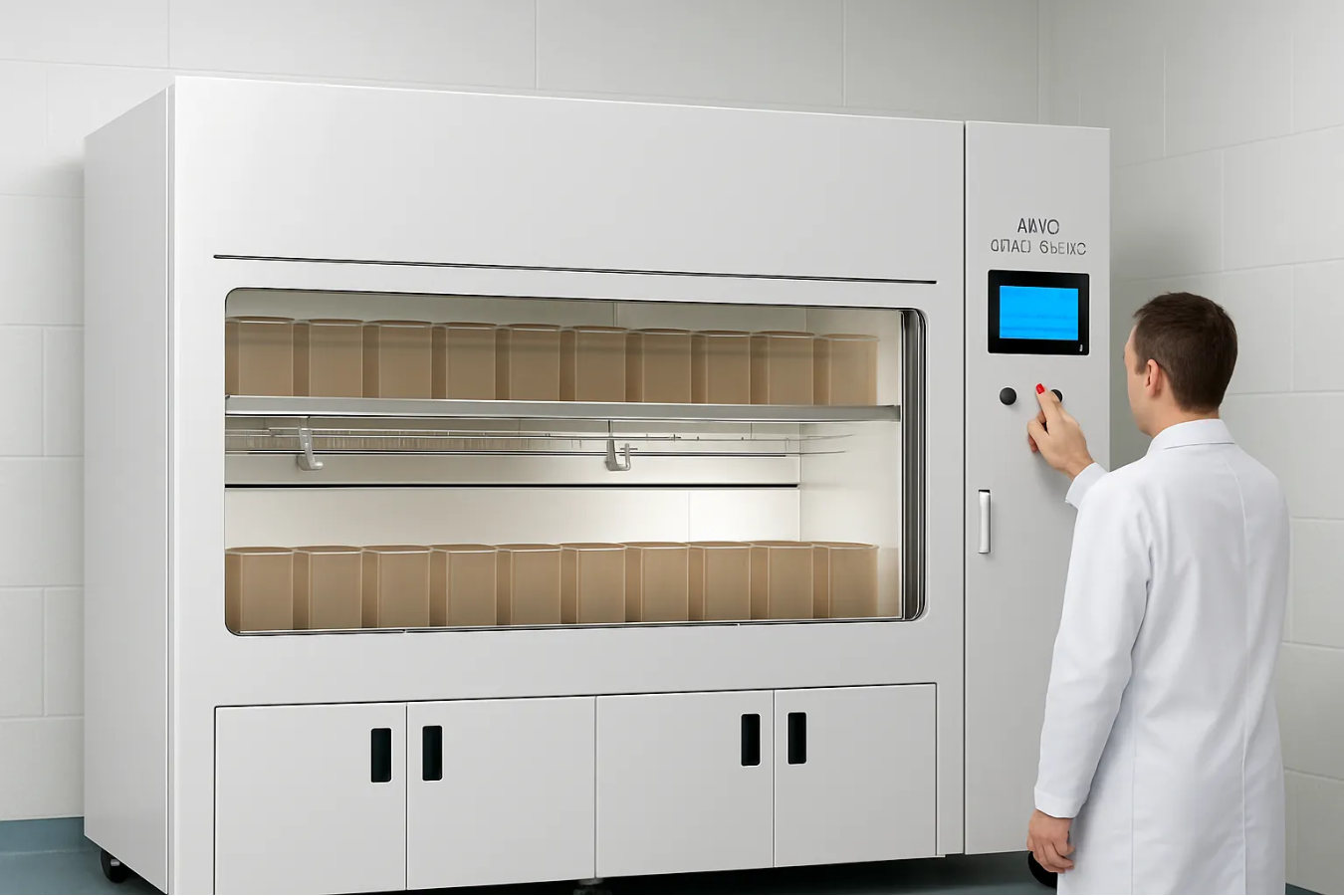

An automatic animal cage washer is a specialized machine that cleans, washes, and dries animal cages through a fully automatic process.

These machines are commonly used in laboratory animal science facilities and have features like pre-rinse cycles, high-pressure jets, disinfection options, and temperature control.

Many models also include programmable cycles and data logging systems to maintain quality assurance and traceability.

Manual cage cleaning involves human workers taking apart the cages, scrubbing the parts by hand with brushes or using power washers, and then rinsing them with hot water and disinfectants.

This method is mostly used in small-scale facilities, but it is very labor-intensive and relies heavily on the skill and attention of the cleaning staff. Manual cleaning does not offer the consistency and documentation that automated systems provide.

The following table summarizes the key differences between automatic animal cage washers and manual cage cleaning:

| Feature | Automatic Cage Washer | Manual Cleaning |

|---|---|---|

| Cleaning Consistency | High and programmable | Variable, depends on staff |

| Time Efficiency | Fast (4–7 minutes per cycle) | Slow (15–30 minutes or more per cage set) |

| Labor Requirement | Very little supervision is needed | High physical effort and supervision |

| Water and Energy Use | Optimized, with recycling features | Often excessive and wasteful |

| Initial Cost | High expense (purchase and installation) | Low initial cost |

| Long-Term Cost Efficiency | High (good savings over time) | Low (recurring labor and cleaning issues) |

| Audit and Compliance Support | Built-in data logging, traceability | No formal tracking, lacks consistency |

| Suitability for Large Facilities | Excellent | Poor scalability |

Cage cleaning in animal facilities is not limited to just removing visible dirt. It also includes eliminating organic residues, harmful germs, chemical contaminants, and biohazards.

Facilities must follow regulatory guidelines such as Good Laboratory Practices (GLP), ISO standards, and animal welfare regulations. Therefore, the cleaning method should be thorough, consistent, and able to prevent cross-contamination.

To decide which method is better, we need to look at the most important factors: cleaning quality, time efficiency, labor requirements, water and energy usage, cost implications, and compliance with industry standards.

Automatic cage washers consistently provide a high level of sanitation through calibrated and repeatable processes. These machines use accurate water pressure, controlled temperature, and precise chemical dosing to make sure every surface is properly disinfected.

Manual cleaning, on the other hand, is vulnerable to human error. Inconsistencies in scrubbing, rinsing, or applying disinfectant can lead to poor sanitation, which may affect animal health and research results.

Automated systems are made for speed and handling volume. A modern washer can clean up to 40 mouse IVC cages in a single cycle that lasts only five to seven minutes. Cleaning the same number of cages manually would take much longer and require several workers.

The time saved with automated systems allows technicians to focus on more important tasks related to animal care and facility management.

Manual cleaning involves a lot of physical work and repetitive actions, which can lead to fatigue or work-related injuries over time. Automatic washers lower the need for human labor and reduce the risk of mistakes.

This not only improves working conditions but also reduces the amount of training needed for cleaning staff.

Although automatic washers use electricity and water, they are designed for efficiency. Many models have water recycling systems and energy-saving modes.

Manual cleaning may seem less technical, but it often leads to more water wastage and inconsistent use of disinfectants, especially if staff are not properly trained or supervised.

The upfront cost of buying and installing an automatic cage washer is high. However, over time, the lower labor costs, water savings, and fewer hygiene failures usually make the investment worthwhile.

Manual cleaning seems cheaper at first, but it brings ongoing costs for labor, time, training, and possible fines if hygiene standards are not met.

Many automatic washers have built-in logging systems that record each cycle, making it easy to provide proof for audits and inspections.

Manual cleaning lacks this kind of traceability, so it is harder to prove compliance with animal care regulations or quality control standards.

Despite its disadvantages, manual cleaning can still be a viable option in certain contexts. Small animal shelters, low-budget clinics, or facilities with minimal cage volume may not need the throughput of an industrial washer.

In such settings, careful and consistent manual cleaning with adequate training and strict protocols can still achieve acceptable hygiene levels.

However, as the volume of work increases or regulatory compliance becomes stricter, manual cleaning often becomes unsustainable.

While the initial cost of automated washers can be high, their benefits increase over time. These machines reduce repetitive labor, improve staff safety, and consistently meet health and research quality standards.

Facilities that focus on long-term growth, efficiency, and audit readiness are increasingly investing in automated solutions.

Additionally, many newer models offer extra features such as HEPA-filtered drying, programmable chemical dosing, touchscreen interfaces, and steam sterilization options.

These upgrades help institutions future-proof their sanitation infrastructure and stay compliant with changing standards.

From a scholarly and practical standpoint, automatic animal cage washers offer significant advantages for medium to large research facilities, pharmaceutical companies, and academic institutions.

Their precision, repeatability, and labor-saving capabilities far outweigh the traditional method of manual cleaning.

For institutions prioritizing compliance, efficiency, and hygiene, automated cleaning systems are not just a convenience but a necessity.

Choosing between automatic and manual cage cleaning depends on your facility’s scale, budget, and regulatory requirements.

Manual cleaning may seem cost-effective at first, but the long-term benefits of automatic cage washers cannot be denied. Better hygiene, labor efficiency, traceability, and compliance make them the better option for most animal care environments.

Institutions that value safety, precision, and scalability should seriously consider moving to automated cleaning systems. This decision is not just a technology upgrade, but also a step toward higher operational standards.

Are automatic cage washers difficult to maintain?

No. Most modern washers are designed with modular components, self-cleaning cycles, and easily accessible parts for maintenance. Regular preventive servicing ensures reliable performance.

How long does an automatic cage washer last?

With proper maintenance, these machines can operate effectively for ten to fifteen years, depending on usage frequency and environment.

Is staff training needed for using automatic washers?

Yes, basic training is required. However, most machines have user-friendly interfaces, programmable settings, and touchscreens, making training straightforward.

Can automatic washers handle different cage sizes and materials?

Yes. Most commercial models are compatible with a wide range of cage materials, including stainless steel and polycarbonate. Adjustable racks and spray arms accommodate various shapes and sizes.

Does manual cleaning meet GLP or ISO standards?

Manual cleaning can meet standards if proper protocols, record-keeping, and validation procedures are followed. However, automation ensures better compliance with less human variability.

Since 1992, Applied Physics Corporation has been a leading global provider of precision contamination control and metrology standards. We specialize in airflow visualization, particle size standards, and cleanroom decontamination solutions for critical environments.